Channels

Special Offers & Promotions

Quorum Reports on How Cryo Prep Techniques for SEM are Being Applied in the Laboratory of Food Technology & Engineering at the University of Ghent, Belgium

Quorum Technologies, market and technology leaders in electron microscopy coating and cryogenic preparation products, report on how the Laboratory of Food Technology & Engineering at the University of Ghent, Belgium, applies cryo techniques to prepare food samples for study by scanning electron microscopy.

Ir Davy Van de Walle is a senior researcher in the Laboratory of Food Technology & Engineering at the University of Ghent. He works for the head of the laboratory, Professor Koen Dewettinck. Their mission is to design foods on the nano- and microscale which provide the answer to the consumer demand for new products that are tasty, satisfying, healthy, convenient and inexpensive to produce. Moreover, this may create added value to by-products and contribute to overall socio-economic welfare. Put more simply, they want to understand how ingredient interactions and processing affect the quality attributes (texture, mouthfeel and taste among others) of foods (dairy products, margarines/shortenings and chocolate products in particular). The challenge of imaging using scanning electron microscopy (SEM) is the ability to keep the samples in their natural state hence the requirement to employ cryo sample prep and the selection of Quorum's PP3000T system for the task.

Ir Davy Van de Walle is a senior researcher in the Laboratory of Food Technology & Engineering at the University of Ghent. He works for the head of the laboratory, Professor Koen Dewettinck. Their mission is to design foods on the nano- and microscale which provide the answer to the consumer demand for new products that are tasty, satisfying, healthy, convenient and inexpensive to produce. Moreover, this may create added value to by-products and contribute to overall socio-economic welfare. Put more simply, they want to understand how ingredient interactions and processing affect the quality attributes (texture, mouthfeel and taste among others) of foods (dairy products, margarines/shortenings and chocolate products in particular). The challenge of imaging using scanning electron microscopy (SEM) is the ability to keep the samples in their natural state hence the requirement to employ cryo sample prep and the selection of Quorum's PP3000T system for the task.

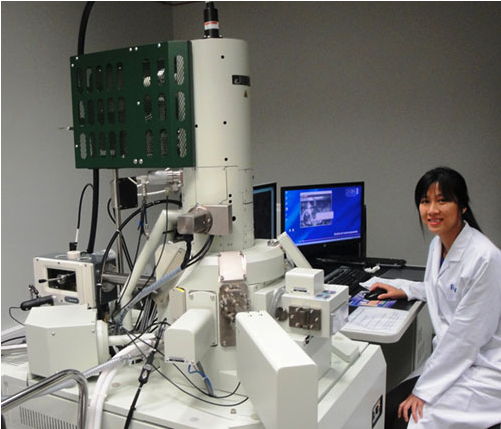

Mr Van de Walle describes the background and execution of the imaging process in detail: “Because a field emission gun (FEG) is used in high resolution SEM, it needs to be placed in an ultra-high vacuum of 10-7 to 10-8 Pa. Consequently, these extreme vacuum conditions require that the specimen must not release any gas or vapour when inserted into the SEM. Except for powdered foods such as flour, sugar or milk powder, most foods contain water. Scanning electron microscopes at lower vacuum conditions (Low-Vacuum SEM, Variable Pressure SEM and Environmental SEM) can be used to examine wet, oily and non-conductive samples in their natural state. In this way, there is no need to dry or freeze the specimen. This is particularly useful with fragile food samples. However, cryo-SEM is the most appropriate technique in food research because of its extremely high resolution. The goal of the cryo-SEM is to vitrify the liquid phase with all the constituents, i.e. macromolecules, thus preserving them in their natural and original state. This process is achieved with the use of the Quorum PP3000T cryo sample preparation system. The initial rapid cooling of the sample is the most critical part in the use of the cryo-SEM system. A slush of liquid N2 (-210 °C) is used for the fast freezing to minimize any damage ice crystals may cause. Following, the sample is transferred under vacuum to the cold stage of the preparation chamber, which is mounted on the SEM chamber. The sample can be fractured to expose internal microstructure, etched to reveal greater detail and coated with metal (e.g. Pt) by sputtering. Finally, the sample is transferred into the SEM chamber where it is mounted on a cold stage specifically tailored to the SEM.” Describing the background to choosing the Quorum sample preparation system, Mr Van de Walle said the process followed a tender procedure involving several FEG-SEM vendors. “Several companies (e.g. Jeol and Hitachi) offered their FEG-SEM in combination with the Quorum preparation chamber. During our meetings with these suppliers, they recommended Quorum as being the best performing. We have been very satisfied with our choice and the group has started to publish papers where the cryo prep system has been invaluable. One example is the PhD research1 of Dr Phuong Diem Tran in which the applicability of cryo-SEM for storage stability testing of pralines is reported. These pralines suffered from fat and sugar bloom. These phenomena are illustrated in the images below. Further work including the fat bloom examples have been published in a paper in the European Journal for Lipid Science Technology.”

Media Partners