Channels

Special Offers & Promotions

The Physics Department of Imperial College, London, Uses the Quorum Q150T to Deposit Metals and ITO to Make Plasmonic Sensors and Electric Contact Pads

Quorum Technologies, market and technology leaders in electron microscopy coating and cryogenic preparation products, talk about how the Blackett Laboratory of the Physics Department at Imperial College chose the Q150T coater to deposit metals to make plasmonic devices in a fast prototyping and development process.

Dr Avi Braun is a Research Associate in the Faculty of Natural Sciences, Department of Physics at Imperial College, London. Located in the Blackett Laboratory, Dr Braun joined the Quantum photovoltaic group in December 2013 as an Imperial College Junior Research Fellow. His main subject of research is the harnessing and integration of nano-photonic structures with photovoltaic and other opto-electronic and sensing applications. This research involves the design, simulation, fabrication and characterization of miniaturized opto-electronic devices and plasmonic sensors.

Dr Avi Braun is a Research Associate in the Faculty of Natural Sciences, Department of Physics at Imperial College, London. Located in the Blackett Laboratory, Dr Braun joined the Quantum photovoltaic group in December 2013 as an Imperial College Junior Research Fellow. His main subject of research is the harnessing and integration of nano-photonic structures with photovoltaic and other opto-electronic and sensing applications. This research involves the design, simulation, fabrication and characterization of miniaturized opto-electronic devices and plasmonic sensors.

Dr Braun uses the Quorum Technologies Q150T coater to deposit a variety of metals and ITO (indium-tin oxide) to make plasmonic sensors and electric contact pads. Describing what he particularly likes about the Q150, Dr Braun says “In comparison with more sophisticated high vacuum systems, the Q150T is much faster thus allowing us to have a fast prototyping and development process. It is also very simple to use; this enables us to give students access to the system as part of their academic practical training. The metals we use include gold, silver, ITO and a nickel-copper alloy. These we deposit in a thickness range of 50-150 nm. We also put down adhesion layers of chromium and titanium to a thickness of 3-5 µm. We particularly like the way we are able to change targets – fast and simple. We also find the angled rotational stage very good for coating 3D structures.”

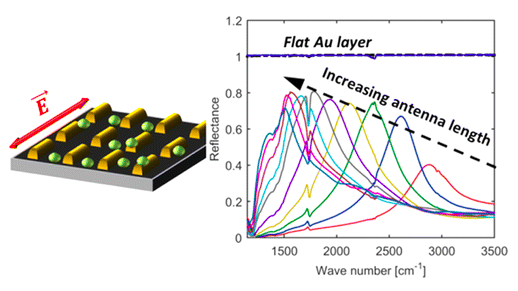

Dr Braun and his colleague, Professor Stefan Maier, have published work in ACS Sensors. It describes the fabrication of plasmonic IR sensors using direct laser writing and metal deposition using the Q150T system. Entitled “Versatile direct laser writing lithography technique for surface enhanced infrared spectroscopy sensors”, the paper is available online through the American Chemical Society at ACS Sens., 2016, 1 (9), pp 1155–1162, OID: 10.1021/acssensors.6b00469.

more about quorum technologies

more news from quorum technologies

Media Partners