Channels

Special Offers & Promotions

The need for digital workflows to characterise fuel cell materials

Deep Learning for Pore Backs with Thermo Scientific™ Avizo™ Software: Overcoming Segmentation inaccuracy due to Pore backs*.

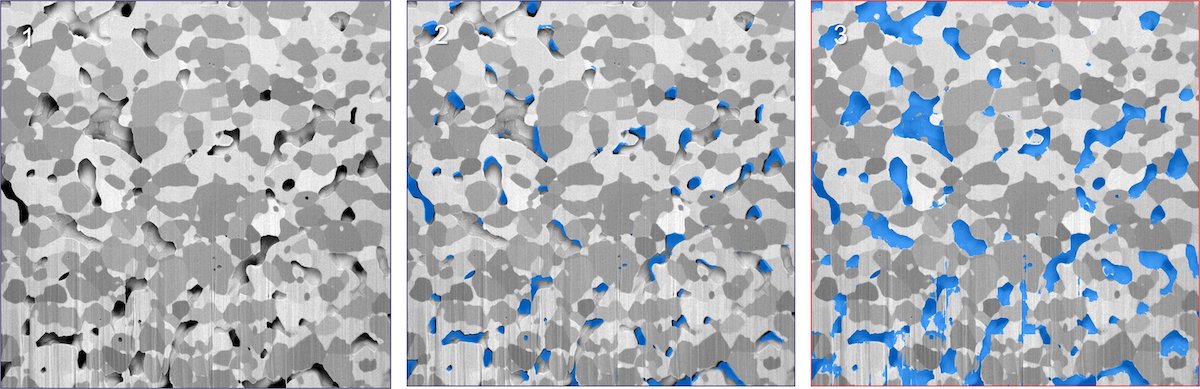

Figure 1: Original SEM data.

Figure 2: Traditional imaging processing of pores.

Figure 3: DL segmentation of pores.

*Data courtesy of Sabanci University, Turkey

How integrated imaging and AI-assisted segmentation can advance fuel cell research

Fuel cells are powering a growing number of clean energy technologies, from electric vehicles to grid-scale power solutions. With their quiet operation, high energy density and zero emissions at the point of use, they offer a compelling alternative to combustion-based technologies. But scaling fuel cells for widespread adoption depends on a deeper understanding of the materials that impact their performance and reliability. Here, Daniel Phifer, Material Science Electron Microscopy Product Specialist at Thermo Fisher Scientific, explores how digital workflows can help to gain this understanding.

Solid oxide fuel cells (SOFCs) are built from intricate, porous, multi-phase materials that must balance competing requirements such as strong ionic conductivity, gas permeability, mechanical strength and thermal stability. The fine balance between these properties is determined by the material’s microstructure: how grains connect, how pores are distributed and how tortuous the flow paths are. In SOFCs, lower tortuosity typically correlates to better gas diffusion and ionic transport, which can improve the efficiency of the fuel cell.

However, getting the balance of each of these properties right demands highly accurate materials characterisation and analysis, which traditional techniques are struggling to deliver.

Limits of conventional characterisation

Modern fuel cells typically include ceramic electrolytes, porous electrodes and metal-supported structures, each with intricate microstructures that span multiple length scales. Their performance depends not only on individual material phases but also on how these components interact, with networks of pores and solid phases affecting how ions and gases move through the structure.

Traditional materials characterisation methods such as 2D imaging and manual segmentation can fall short when applied to such complex materials. Conventional 2D imaging captures only a single plane of the material, often missing critical information about the three-dimensional connectivity of pores and grains. Manual segmentation methods introduce further limitations as they rely heavily on user-defined thresholds and visual interpretation, which can vary significantly between analysts and datasets. As a result, these approaches can lead to incomplete or misleading representations of a material’s true structure.

Another common issue is the presence of pore-back artefacts in scanning electron microscope (SEM) imaging. These artefacts are caused by the electron signal capturing the internal surfaces of the pore and artificially inflating porosity estimates.

Even if artefacts are minimal, typical workflows still require repeated manual tuning, including adjusting image contrast, selecting regions of interest and interpreting ambiguous features. As well as slowing down the process, these steps increase the risk of inconsistency, which is particularly problematic given the incredibly slim margin for error when dealing with such complex microstructures.

The promise of digital workflows

To overcome these limitations, many researchers are instead turning to digital workflows, encompassing high-resolution imaging, advanced segmentation and simulation to generate more accurate, reproducible data.

Crucially, digital workflows remove much of the subjectivity that has traditionally occupied image interpretation. Advanced segmentation, particularly when powered by machine learning, can be trained to detect subtle structural differences and correct for known artefacts, such as pore-back effects.

A digital workflow begins with the acquisition of high-quality 3D image data, followed by automated or AI-assisted segmentation and then computation of relevant properties such as pore volume, surface area and transport pathways. This approach greatly reduces user variability and speeds up the analysis cycle.

By digitalising the entire process, teams can generate consistent, simulation-ready models that reflect the true physical properties of materials. Once established, a digital pipeline can be applied across different samples, materials or experimental conditions, enabling high-throughput analysis without compromising accuracy.

A digital workflow in action

A practical example of a digital workflow for fuel cell analysis combines the Thermo Scientific™ Helios™ PFIB DualBeam with Thermo Scientific™ Avizo™ Software. Together, these tools create an end-to-end solution designed specifically to handle the complexity of materials like those found in SOFCs.

The process begins with the Helios PFIB DualBeam, which integrates focused ion beam (FIB) milling with high-resolution SEM imaging. By performing serial sectioning, the system generates detailed 3D image stacks that capture the full internal architecture of a sample. With support for large-volume milling, cryo protection and inert gas transfer, this system can accommodate a wide variety of fuel cell materials and preparation conditions.

Once imaging is complete, the dataset is then transferred into Avizo Software, which uses AI-assisted segmentation to extract meaningful structures from the image data. Unlike manual methods, Avizo uses deep learning models trained to recognise pores, grain boundaries and pore-back artefacts. This leads to much more accurate segmentation of the pore space, which is critical for evaluating gas transport and ionic conductivity.

In addition, Avizo also allows researchers to build a Pore Network Model: a digital representation of the void space between grains. Using this model, key transport-related properties such as tortuosity can be computed, helping to improve performance predictions and inform fuel cell design.

In one real-world application, this combined workflow helped researchers avoid a 250 per cent overestimate in porosity. On average, the deep learning segmentation delivered a 6.7 per cent correction per image slice, offering a far more accurate representation of the material’s internal structure.

With the demand for high-performance and low-emission energy solutions only likely to grow, it’s crucial to finesse our understanding of the materials that make them possible. In the case of fuel cells, where even small differences in complex internal microstructures can significantly impact efficiency, traditional characterisation methods are no longer sufficient. Digital workflows offer a more accurate and scalable approach to help researchers visualise and quantify the intricacies of fuel cell structures with greater precision and fewer artefacts. This insight into material behaviour will be critical to develop the next generation of energy technologies.

The Thermo Scientific™ Helios™ PFIB DualBeam is the result of 30 years of DualBeam innovation, designed to meet the evolving demands of materials science. To find out how this solution can help accelerate your materials research, please get in touch.

About Thermo Fisher Scientific

Thermo Fisher Scientific Inc. is the world leader in serving science, with annual revenue over $40 billion. Our Mission is to enable our customers to make the world healthier, cleaner and safer. Whether our customers are accelerating life sciences research, solving complex analytical challenges, increasing productivity in their laboratories, improving patient health through diagnostics or the development and manufacture of life-changing therapies, we are here to support them. Our global team delivers an unrivaled combination of innovative technologies, purchasing convenience and pharmaceutical services through our industry-leading brands, including Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific, Unity Lab Services, Patheon and PPD.

Recent news from Thermo Fisher Scientific

Media Partners