Channels

Special Offers & Promotions

Elevating sample preparation for advanced SEM analysis

How to overcome challenges with maintaining sample integrity

In materials science, achieving precise and repeatable scanning electron microscopy (SEM) analysis requires pristine sample surfaces. However, handling and preparation methods frequently degrade the sample’s condition, making it challenging to observe the material's essential features. Here, Britta Siefer, SEM expert at Thermo Fisher Scientific, explains how a reliable workflow can preserve sample integrity for quality analysis.

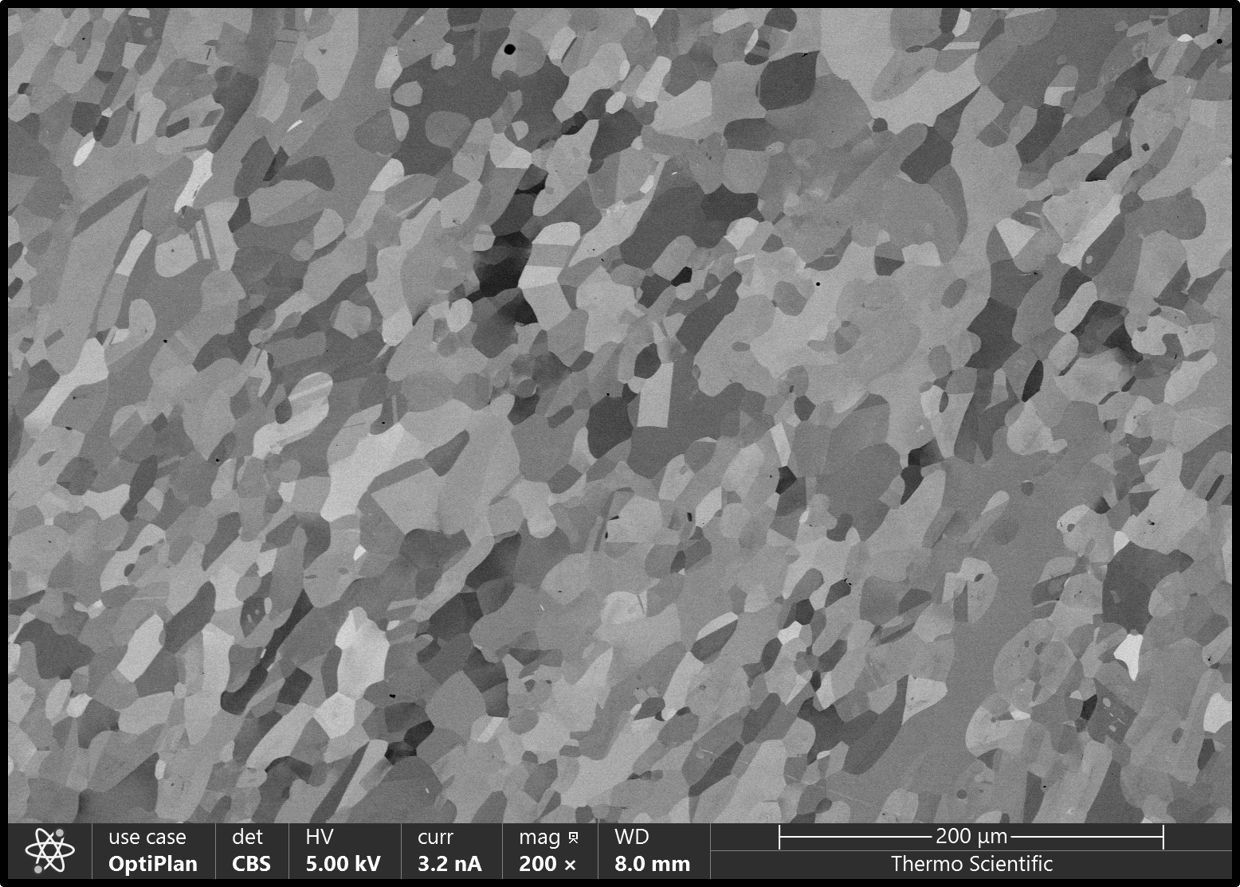

Industries like energy storage and metallurgy are driving progress by engineering materials at the microscopic scale. This relies on precise material characterisation using advanced SEM techniques such as elemental dispersive spectroscopy (EDS) and electron backscattered diffraction (EBSD). However, for these techniques to deliver accurate insights into material properties, they require smooth, defect-free sample surfaces — a challenge when working with air-sensitive or delicate materials.

Balancing preparation and contamination

The first hurdle in obtaining clean samples lies in the preparation process, a prerequisite for successful imaging. Without proper preparation, contaminants and surface irregularities can interfere with the characterisation of microstructural features, leading to unreliable or incomplete data.

One of the most widely used preparation methods is mechanical polishing using abrasives like fine sandpaper to smooth surfaces. While this achieves the intended smoothing effect, it also introduces artifacts such as scratches, smearing and distortions. These artifacts can obscure features of interest in the sample and make it difficult to discern characteristics such as grain boundaries, phases or nanoparticle distributions.

Composite materials present additional challenges during preparation. These materials often have complex multi-phase structures, combining elements like metals, ceramics and polymers. Preparing these samples requires precise cutting or the surface can be damaged.

Protecting samples during transport

Once a sample is prepared, it must be transferred to a SEM for analysis. Since even the most meticulously prepared samples can be compromised, the transport stage requires extreme care.

Some materials are particularly susceptible to damage during this stage, especially those used in advanced industries such as energy storage and aerospace. Next generation alloys for aerospace applications and lithium-based compounds, commonly used in battery research, are highly prone to oxidation or hydration upon exposure to air. For instance, lithium-based materials react rapidly with moisture, causing surface corrosion that makes it impossible to accurately assess their composition or morphology.

Traditional non-automated transfer systems like standard vacuum chambers are frequently used to mitigate exposure during transport. However, these systems often fall short in providing adequate protection for air-sensitive materials. Many lack the necessary automation to continuously monitor and control critical environmental parameters such as temperature, humidity and gas composition. Fluctuations in these factors can lead to material degradation and significant alterations to the sample’s surface.

These inconsistent transport conditions not only obscure results but also undermine the reliability and repeatability of SEM analysis. This can force materials scientists and engineers to repeat sample preparation and analysis, resulting in wasted time, resources and potentially compromised findings.

Refining processes

As preparing and transferring samples can compromise sample integrity, it’s crucial to establish a reliable workflow. Thermo Fisher Scientific’s Red Design Concept Award winning CleanMill Broad Ion Beam System was designed to eliminate challenges in sample preparation and transfer, maintaining pristine, artifact-free sample surfaces for advanced SEM analysis.

This system uses a broad beam of argon ions to smooth the surface of a sample, destroying the artifacts commonly introduced by techniques such as mechanical polishing. This ensures that only the material’s inherent characteristics are analysed, rather than any defects caused by preparation methods. The CleanMill’s ion beam can also be used for planar cross-sections, enabling researchers to analyse the intricate layering, interfaces and phase boundaries in materials such as composite structures, which can be challenging to prepare using traditional methods.

With a flexible energy range from 0.1 kV to 16 kV, the CleanMill is versatile enough to accommodate a wide range of materials and is optimised for high-throughput processing, making it ideal for repeatable analysis in large-scale operations.

Additionally, the CleanMill integrates into a comprehensive automated workflow designed to protect samples during transport to the SEM. Using the CleanConnect Sample Transfer System, part of the Inert Gas Sample Transfer (IGST) Workflow, samples are securely enclosed in an argon environment, preventing damage from oxidation or hydration. This integrated approach significantly improves the reliability of SEM analysis by preserving the condition of the sample from preparation through to analysis.

Performing high-quality, repeatable SEM analysis hinges on the ability to preserve samples during the preparation and transfer stages. Maintaining pristine sample surfaces is therefore a priority for advancing materials science. With high-quality tools and seamless workflows, researchers can continue to gain new insights into the properties and performance of materials at the microscopic level, unlocking potential breakthroughs across industries.

To find out how Thermo Fisher Scientific could help you to implement a reliable workflow for advanced SEM analysis, please contact a member of the team.

About Thermo Fisher Scientific

Thermo Fisher Scientific Inc. is the world leader in serving science, with annual revenue over $40 billion. Our Mission is to enable our customers to make the world healthier, cleaner and safer. Whether our customers are accelerating life sciences research, solving complex analytical challenges, increasing productivity in their laboratories, improving patient health through diagnostics or the development and manufacture of life-changing therapies, we are here to support them. Our global team delivers an unrivaled combination of innovative technologies, purchasing convenience and pharmaceutical services through our industry-leading brands, including Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific, Unity Lab Services, Patheon and PPD.

Recent news from Thermo Fisher Scientific

Media Partners