Channels

Special Offers & Promotions

The role of technical cleanliness in manufacturing

How manufacturers can leverage microscopy for more reliable products

Manufacturers are constantly seeking faster, more effective methods of producing parts. But to achieve the best quality final products, it’s crucial not to rush the technical cleanliness process. Here, Salomé Larmier, electron microscopy specialist at Thermo Fisher Scientific, explains why technical cleanliness is critical and how to achieve it using microscopy techniques.

Technical cleanliness refers to components being free of contaminants such as particles, fibres or dust, which can disrupt the manufacturing process, undermine the quality of the final product and even pose health risks to users due to harmful particles like asbestos. Though often associated with automotive manufacturing, cleanliness analysis is vital in a number of sectors, including electronics and aerospace.

Contamination risks

Even miniscule (from µm to nm) levels of contaminants can have a significant impact on a component’s functionality and durability. For example, tiny metallic particles can cause premature wear or even seizure in precision bearings and hydraulic systems by disrupting the lubricating film separating moving parts. In safety-critical applications like anti-lock braking systems (ABS), a seized hydraulic actuator could result in lost control and instability during emergency braking.

In electronic components, contaminants such as conductive residues left behind during manufacturing can cause short circuits or corrosion over time, especially under thermal cycling. The effects of contamination are often cumulative and can lead to latent failures that are difficult to trace, which is why stringent cleanliness procedures are essential.

Clean surfaces are critical for the effective application of coatings, adhesives and surface treatments. Any residual contamination can compromise adhesion, ultimately impacting the product’s long-term reliability.

Technical cleanliness is also a requirement in many industries. In automotive manufacturing, for instance, compliance with established standards such as ISO 16232 and VDA 19 is mandatory to ensure the cleanliness of fluid-bearing components.

Barriers to cleanliness

Maintaining technical cleanliness in manufacturing can be challenging due to the complexity of the processes involved and the resources required. Manual cleaning and inspection, in particular, require highly skilled operators and can slow down production.

Another challenge is the variety of contaminants and the methods used to remove them. Metallic particles, fibres and chemical residues each require different cleaning techniques, such as ultrasonic cleaning, vacuum extraction and solvent treatments, respectively.

Additionally, the detection systems used must be incredibly sensitive in order to identify any micron-level contaminants, as stipulated by industry standards. For some manufacturers, such as those in automotive and other high-precision sectors, identifying the size of the particles alone is not enough — they also need to characterise the shape and even the chemical composition of particles. This is where microscopy plays a pivotal role.

Optical or SEM?

ISO 16232 and VDA 19 reference two different types of microscopes for technical cleanliness: optical microscopy and scanning electron microscopy. One of the most common ways to collect particles for analysis using either microscope is by collecting particles from a cleaning filter after washing components.

Optical microscopes are widely used for their speed and simplicity, as they are capable of scanning an entire filter in just five to ten minutes. Since they detect particles based on visual contrast, they are highly effective at analysing dark contaminants on light backgrounds, though they struggle to detect light-coloured or transparent particles such as glass.

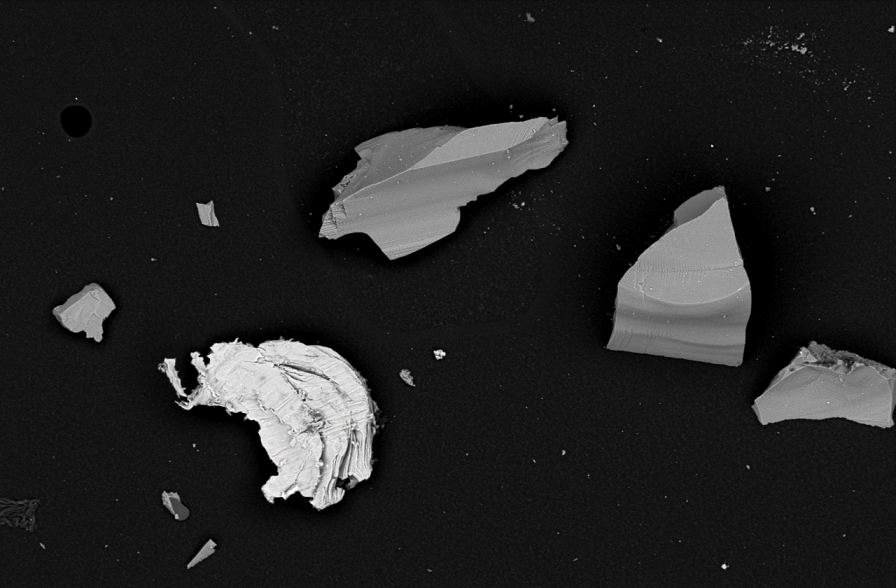

On the other hand, scanning electron microscopes (SEM) use backscattered electrons to create contrast based on atomic number. This allows them to detect a wider range of materials, including those that optical systems might miss. Additionally, secondary electron detectors collect low-energy electrons emitted from a sample’s surface, providing detailed topographical information crucial for imaging. Their sensitivity to surface features makes them essential for high-resolution analysis, while also helping identify potential risks from hazardous materials present on the surface. Finally, SEMs can be paired with energy-dispersive X-ray spectroscopy (EDS) to determine the elemental composition of each particle and thus provide valuable insight into contamination sources.

While SEMs traditionally take longer, modern integrated systems with automated scanning and EDS analysis can now process entire filters rapidly. For example, the Thermo Scientific™ Axia™ ChemiSEM with Perception Particle Analysis Software can scan complete filters within 20 minutes. While an optical microscope may be faster, the added time taken up to complete this analysis yields much more detailed insights. Additionally, the integrated EDS capability allows operators to select and analyse particles of interest in real time, eliminating extra correlation steps that can slow down the process.

Ultimately, the most suitable microscopy technique depends on each application’s specific requirements. However, as technical cleanliness standards become more and more rigorous, scanning electron microscopy offers a future-proofed solution capable of delivering detailed analysis on a sub-micrometer scale. By investing in advanced microscopy solutions and integrated cleanliness workflows, manufacturers can stay ahead of the curve and ensure their products meet the highest standards of quality and performance.

Thermo Fisher Scientific is a global leader in scanning electron microscopy and has a wealth of experience in supporting quality assurance across a range of industries. To find out how SEM could enhance your technical cleanliness workflow, get in touch with our team.

About Thermo Fisher Scientific

Thermo Fisher Scientific Inc. is the world leader in serving science, with annual revenue over $40 billion. Our Mission is to enable our customers to make the world healthier, cleaner and safer. Whether our customers are accelerating life sciences research, solving complex analytical challenges, increasing productivity in their laboratories, improving patient health through diagnostics or the development and manufacture of life-changing therapies, we are here to support them. Our global team delivers an unrivaled combination of innovative technologies, purchasing convenience and pharmaceutical services through our industry-leading brands, including Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific, Unity Lab Services, Patheon and PPD.

Recent news from Thermo Fisher Scientific

Media Partners