Channels

Special Offers & Promotions

Why SEM makes sense for industry

Choosing the right scanning electron microscope to drive innovation and product integrity

Materials innovation is at the heart of industry, from the battery technology for electric vehicles to the metals making aircraft lighter. Understanding the physical and chemical properties of materials — from the macro to nano scale — is therefore the fuel for continued industrial advancement. Whether discovering new materials or working to overcome challenges with existing products, scanning electron microscopy (SEM) is a valuable instrument for industry. Here, Britta Siefer, Senior Sales Account Manager at industrial SEM specialist Thermo Fisher Scientific, explains the considerations when investing in an SEM microscope for an industrial application.

In the UK, the manufacturing sector is a leading example of innovation activity, with data from the government’s United Kingdom innovation survey 2023 showing that that the nation’s five most innovative industries were all forms of manufacturing. To meet the demands of these industries, advanced imaging technologies that allow manufacturers to thoroughly understand the physical and chemical properties of component materials are key.

Precise imaging is also essential for ensuring product integrity and enhancing quality assurance. According to a 2020 ETQ survey that included respondents from the manufacturing, life sciences and food and beverage sectors, 96 per cent of organisations reported having a product recall in the preceding five years. These quality control issues cause financial losses and reputational damage, especially in highly regulated industries.

SEM as the solution

Scanning electron microscopes enable thorough analysis to drive innovation and eliminate quality control issues. SEMs scan a beam of electrons across the surface of a material sample, with specific detectors to visualise the interaction between the electrons and the sample. The image is then displayed digitally, allowing for a detailed view of the sample at the nanometre level.

Multiple detectors can be used to view and analyse elements that would not be visible with an optical microscope, making it easier to carry out quality control and failure analysis. SEMs offer unmatched capabilities in assessing surface morphology and verifying material composition, as well as investigating the root causes of material failure and fatigue.

For example, within the automotive industry, where even the smallest particle contamination can influence performance, SEM is useful for cleanliness analysis to detect unwanted particles. Thorough analysis ensures that components meet ISO16232 and VDA 19.1 quality standards, which are essential for the functional quality of vehicles.

Likewise, SEM analysis is also vital in the processing of paints and coatings used to protect metallic components such as aerospace engines. By using a microscope that can detect backscattered electrons, engineers can determine how much coverage the coatings provide as well as the different compounds they include. Given the harsh conditions that aerospace components are subject to, identifying potential defects with an SEM is crucial to avoid issues with corrosion, reduced durability and potential failures.

Other industries that can benefit from SEM analysis include battery manufacturing, steel and metal production, additive manufacturing, geology and mineralogy.

Before buying

While scanning electron microscopy offers a range of advantages, it can be difficult for quality control engineers without microscopy expertise to know what to look for when selecting a SEM. To choose the right solution, there are several important considerations to bear in mind.

Firstly, it’s important to consider the specific reasons for using microscopy for quality control and failure analysis. For example, some manufacturers may use SEM to comply with specific industry standards, or to shift away from outsourcing analysis to bring it in house.

The next step should be identifying the size of the features that need imaging, as this can determine the type of microscope that would be most suitable. For features that would not be visible with an optical microscope, an SEM would be preferable.

Finally, it’s important to think about which characteristics of the sample need to be understood. For instance, will SEM be used to analyse the chemical compound of the material? Are to identify defects, such as cracks and unwanted particles? Or will SEM only be required for a quick, general quality control and failure analysis process?

Identifying the ideal SEM

After considering these aspects, it’s time to choose an SEM. Ensure that the microscope’s performance meets any required standards, by taking into account the resolution — the SEM’s ability to distinguish details in the sample. In addition to the imaging element, look for whether it offers advanced detection options such as energy-dispersive X-ray spectroscopy (EDS) for the sample’s elemental composition and electron backscatter diffraction (EBSD) for its crystallographic structure. Opting for an SEM with both solutions can give a greater insight into the chemical and physical properties of a sample, to avoid missing any potential defects.

For quality engineers without extensive microscopy experience, the ideal SEM will have an easy-to-use interface, including intuitive software and controls, as well as the option to automate sample alignment.

Purchasing decisions shouldn’t be limited to the physical aspects of the SEM. For those who are not yet confident in operating microscopes, it’s a good idea to look for a provider that offers training opportunities to help make the most of the SEM.

To further maximise the use of the instrument, it’s beneficial to choose a manufacturer that makes microscope service and maintenance a priority. While some components can be replaced in house, it’s best to contact a specialist engineer for complex parts. Therefore, before buying an SEM, it’s essential to research how and when the solutions provider will offer assistance, and how long this will last.

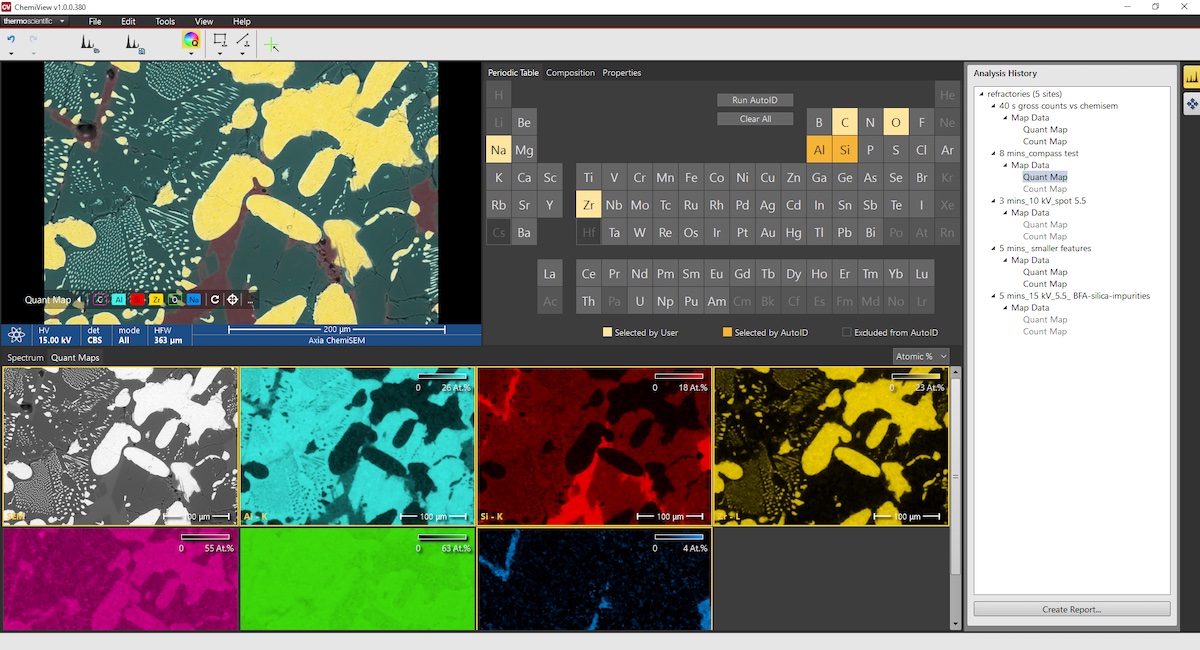

Thermo Fisher Scientific is dedicated to producing analytical scanning electron microscopes that are suited for industry specific needs, offering a wide range of versatile tools from desktop SEM to floor models. For example, Thermo Fisher’sloor standing SEM range includes the Axia ChemiSEM, which uses unique algorithms to facilitate the collection of SEM and EDS signals simultaneously. With a resolution of 3.0 nm @ 30 kV (SE), the Axia ChemiSEM is enhanced by SmartAlign automation technology for sample alignment, allowing for faster, simpler sample characterisation.

As electron microscopy experts, Thermo Fisher also offers reliable, on-demand training tailored to customer and application needs, ensuring easy adoption of its solutions. In addition, Thermo Fisher’s NanoPorts — electron microscopy centres of excellence located across the globe — provide live demonstrations and advice on the right solution for individual applications prior to purchase.

For the manufacturing industry to continuously drive material innovation and product quality, adopting scanning electron microscopy makes sense. However, knowing what to look for in an SEM solution is not always so straightforward. Thoroughly considering microscopy requirements before selecting an SEM allows manufacturers to find a solution that works for them and their quality control process.

About Thermo Fisher Scientific

Thermo Fisher Scientific Inc. is the world leader in serving science, with annual revenue over $40 billion. Our Mission is to enable our customers to make the world healthier, cleaner and safer. Whether our customers are accelerating life sciences research, solving complex analytical challenges, increasing productivity in their laboratories, improving patient health through diagnostics or the development and manufacture of life-changing therapies, we are here to support them. Our global team delivers an unrivaled combination of innovative technologies, purchasing convenience and pharmaceutical services through our industry-leading brands, including Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific, Unity Lab Services, Patheon and PPD.

Recent news from Thermo Fisher Scientific

Media Partners