Channels

Special Offers & Promotions

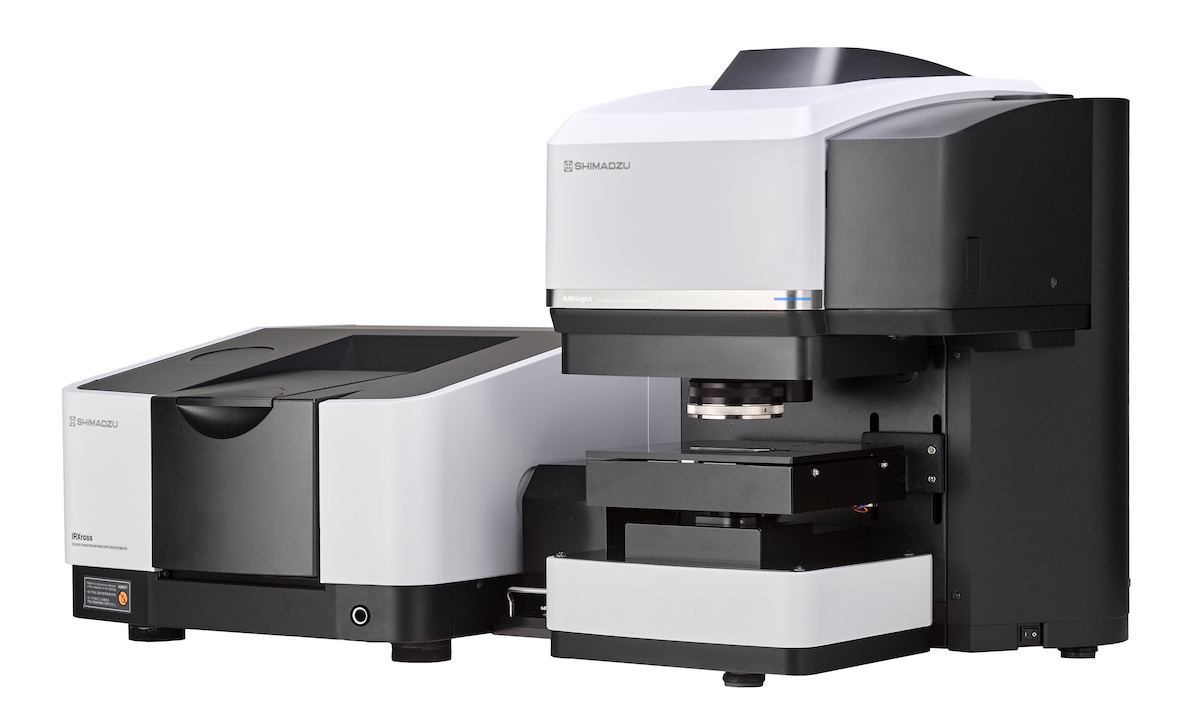

Shimadzu announces the release of the new AIMsight infrared microscope.

Maximized automation significantly improves defect analysis efficiency

Shimadzu, one of the world leaders in analytical instrumentation and testing equipment, announces the release of the new AIMsight infrared microscope. AIMsight builds on the high sensitivity of Shimadzu’s well-known AIM-9000 to offer an improved operational experience through greater automation. AIMsight is intended for industrial applications in a variety of sectors, including drug manufacturing, materials science, electrical devices and electronics, machinery, transportation equipment, and for the environment.

Industry relies on infrared microscopes

An infrared microscope such as AIMsight is used by connecting it to a Fourier-transform infrared (FTIR) spectrophotometer to measure micro-regions using the reflection and transmission of infrared light that cannot be measured by FTIR[1] units alone. The main applications of this are in the analysis and identification of micro-contaminants, such as those adhering to pharmaceutical pills, dirt on electronic circuit boards and microplastics.

Meeting new demands with new instruments

In 2016, Shimadzu introduced the AIM-9000, an infrared microscope equipped with excellent sensitivity and an automatic contaminant analysis function. Since then, the demand for measurements using infrared microscopes has grown rapidly. At the same time – and partly as a result of this – the lack of analysts with experience in such measurements has also grown. The result is that there is now a very strong demand for highly sensitive instruments capable of quick, easy and trouble-free mea-surements of smaller targets. That’s where AIMsight[2] comes in.

Automatic effects

AIMsight meets that demand. It easily – and, importantly, automatically – measures micro-targets by irradiating them with infrared rays and by then investigating the reflectance and transmittance. It features easy determination of the measurement range via a wide-field camera as well as by automatic identification of measurement targets, automatic setting of measurement positions and automatic analysis via a contaminant analysis program.

Keeping you on the environmental cutting edge

Environmental concerns have also increased since 2016. To address those concerns, the AIMsight infrared microscope uses the new T2SL (type-II superlattice) detector. The T2SL does not use mercury or cadmium, which are restricted under the European Restriction of Hazardous Substances (RoHS) Directive for electronic and electrical equipment. The T2SL detector, a so-called quantum infrared detector, has been gaining favorable attention as a high-sensitivity, next-generation infrared sensor.

Not only is AIMsight a more environmentally friendly instrument to own and use, it also is an invaluable tool in trace-contaminant analysis and quality control. Of particular note is the role it can play in researching microplastics, the tiny plastic particles that have such a negative impact on the environment. This is of interest in a variety of fields, ranging from chemistry and electrical and electronic devices to machinery and transportation equipment.

Additional AIMsight advantages

Shimadzu’s AIMsight adds greater environmental awareness and automated functionality to an existing base of impressive attributes, including

Faster searches for measurement sites.

AIMsight is equipped with two optical systems. Shimadzu’s proprietary wide-field camera is not only capable of observations up to 10 × 13 mm in size, it also supports variable digital zooming up to a factor of 330 to a visual field as small as 30 × 40 µm.

The two optical systems share position information, so the observation target being tracked is never lost. AIMsight includes a 330× digital zoom function, and micro-measurement targets are quickly found from the wide-field observations. For inexperienced users, a function is provided that easily identifies the mea-surement target with a simple click on the image in the AMsolution control software and which automatically sets the optimal measurement position in just one second.

Highest sensitivity for micro-measurements

AIMsight provides the highest sensitivity in its class, with a signal-to-noise ratio (S/N ratio) of 30,000:1. High-sensitivity data is quickly acquired even for micro-measurement targets as small as 10 µm. In addition, the length of targets can be measured by selecting the start and end points in the image. A function is included to measure the diameter of microplastic particles.

Automatic contaminant analysis program

After the data is acquired, it can be analyzed automatically by a contaminant analysis program provided as standard with the LabSolutions IR FTIR control software. The contaminant database, which uses a proprietary Shimadzu algorithm, provides high-accuracy analysis results. Qualitative results can be obtained in seconds, with no additional work required by the analyst.

Additionally, qualitative accuracy can be heightened by combining the program with Shimadzu’s own databases: the Contaminant Library, the Thermally Degraded Plastics Library and the UV-Degraded Plastics Library.

Seeing clearly with Shimadzu

Whether addressing environmental concerns directly, helping industry to better do so or assisting instrumentation operators with greater ease through automation, Shimadzu is diligently and continuously assessing the many challenges we face and working to provide solutions: such as AIMsight.

[1] AIMsight can be connected to three FTIR models: IRTracer-100, IRXross and IRAffinity-1S. It cannot be connected to the compact IRSpirit FTIR.

[2] AIMsight, IRTracer, IRXross, IRAffinity and IRSpirit are registered trademarks of the Shimadzu Corporation.

Media Partners