Channels

Special Offers & Promotions

Impact of Powder Properties on the Rheological Behaviour of Excipients

With the emergence of quality by design in the pharmaceutical industry, it becomes imperative to gain a deeper mechanistic understanding of factors impacting the flow of a formulation into tableting dies.

Many flow characterization techniques exist but only a few can mimic the die filling process successfully. One of the challenges in mimicking the die filling process is understanding the rheological powder behaviour and the differences in flow field in the feeding frame.

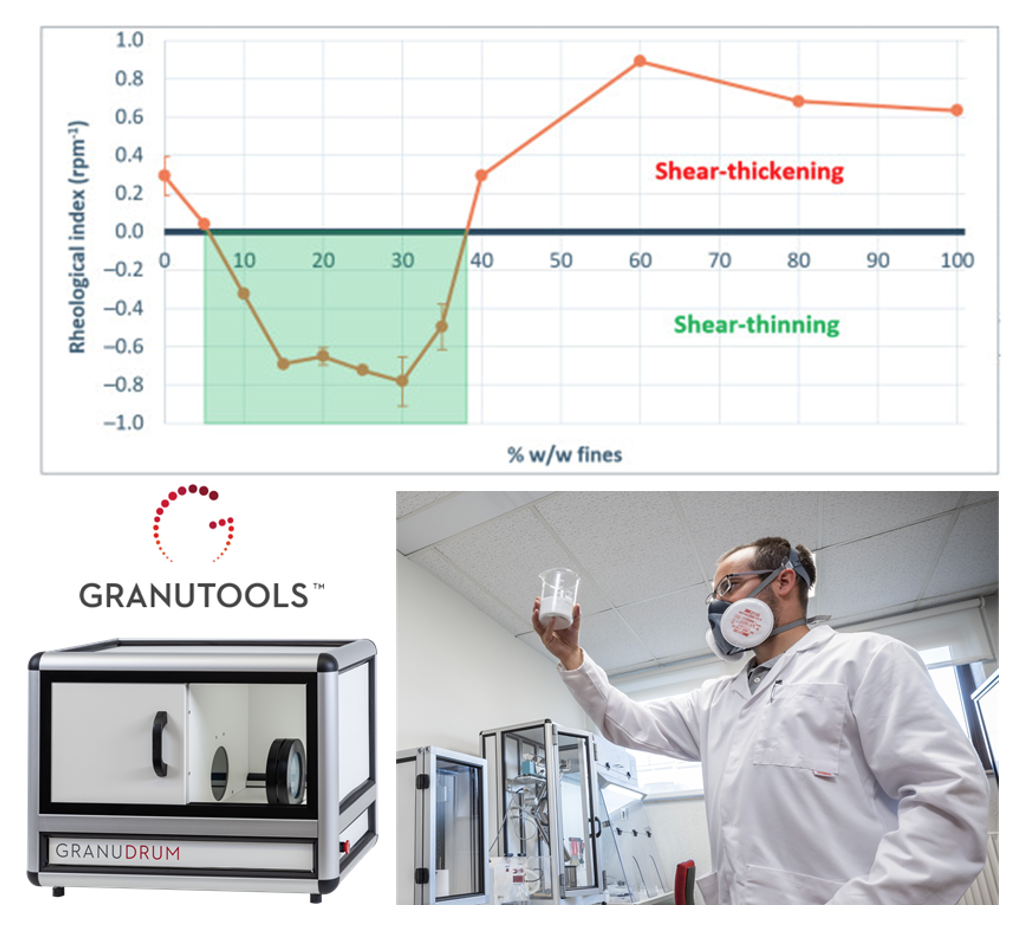

DFE Pharma and GRANUTOOLS joined forces to study a wide range of excipients with a wide range of material properties. A new parameter for rheological behaviour was introduced: the change in dynamic cohesive index upon changes in flow field.

This dynamic cohesive index is directly measured using the GranuDrum instrument. It turns out that the presence of fines between larger particles reduces this rheological index. This phenomenon is explained by an improved particle separation at more dynamic flow fields. The fidelity of the cohesive index was validated by correlating it to tableting performance in a rotary tablet press with agitators.

This study, published in Pharmaceutics, also reveals that GranuDrum measurements provide insights to optimize agitator settings in a tableting machine.

Do you want to know more about this study? Do you want to assess the impact of your powder properties? GRANUTOOLS brings scientific solutions to industrial problems using powder characterization tools. Get in touch with us or visit www.granutools.com.

Media Partners