Channels

Special Offers & Promotions

How to predict powder electrostatics to optimize your loss-in-weight feeder for continuous manufacturing?

In the pharmaceutical industry, the trend is to move from conventional batch manufacturing to continuous manufacturing processes.

The challenges for such change are numerous, but many papers are published to solve those issues and improve production. This is the case of the paper published by Carl Allenspach from Bristol-Myers Squibb (International Journal of Pharmaceutics 596 (2021). In his paper, the authors tackle the problem of electrostatics in loss-in-weight feeders.

Electrostatic forces arise from electric charges lying at the surface of the particles. The contacts between the particles and with the conveying material create electric charges due to the triboelectric effect. This leads to an electric charge build-up that strengthens the electrostatic cohesive interactions. Powder electric charge build-up is commonly accompanied by a decrease in processability. The decrease of flowability due to stronger electrostatic cohesive interactions leads to problems.

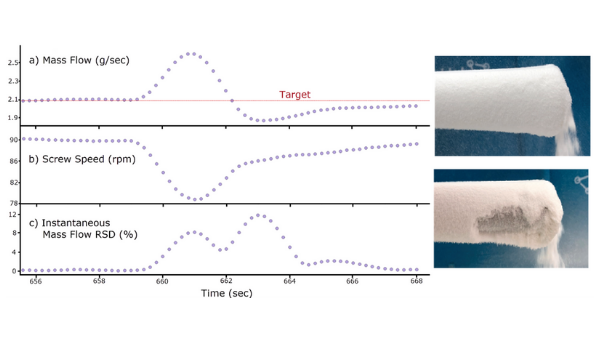

In our case, a loss-in-weight feeder may lose its target due to charge buildup. In a continuous manufacturing process, the charges may not have time to dissipate fast enough since the process never stops. Some powder will stick to the pipes creating a layer of powder outside of the stainless-steel feeding barrel. When the mass of powder stuck outside the pipe is enough to break those electrostatic forces, the powder will fall at once creating large deviations in the mass flow rate (illustrated with the picture above).

Powder flow characterization instruments are designed to be a close proxy of industrial processes and help predict the flowability and processability of powders. In the case of the GranuCharge, the goal of the equipment is to measure the tribocharging effect of a powder, which in this case, will help to predict the processability in the loss-in-weight feeder.

Do you want to learn more about electrostatics? Granutools brings scientific solutions to industrial problems using powder flow characterization tools. Get in touch with us today!

Media Partners