Channels

Special Offers & Promotions

The University of Oxford

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, reports on how the Marrow group in the Materials Department at the University of Oxford applies Deben’s mechanical stage for in situ µXCT studies of multiple engineering and natural materials.

Professor James Marrow leads a research group specialising in the structure-property relationship of a broad range of engineering and natural materials. Based in the Materials Department at the University of Oxford, Marrow's team use high resolution X-ray computed tomography to make in situ studies of three-dimensional deformation and damage (e.g. digital volume correlation), with a particular interest in materials for energy. Research in engineering materials for energy generation is not a quick-fix topic. New materials can take from 15-20 years to come into use and then are expected to be in service for 40-80 years. The key physical mechanisms that determine manufactured performance, and how these properties age in service, are not very well understood, and mistakes in materials selection can have enormous financial and social implications. Prediction is a major challenge and thus a deep understanding of the fundamental mechanisms of materials aging and how it affects damage tolerance is essential to identify and avoid potential “cliff-edges” in future materials performance.

Professor James Marrow leads a research group specialising in the structure-property relationship of a broad range of engineering and natural materials. Based in the Materials Department at the University of Oxford, Marrow's team use high resolution X-ray computed tomography to make in situ studies of three-dimensional deformation and damage (e.g. digital volume correlation), with a particular interest in materials for energy. Research in engineering materials for energy generation is not a quick-fix topic. New materials can take from 15-20 years to come into use and then are expected to be in service for 40-80 years. The key physical mechanisms that determine manufactured performance, and how these properties age in service, are not very well understood, and mistakes in materials selection can have enormous financial and social implications. Prediction is a major challenge and thus a deep understanding of the fundamental mechanisms of materials aging and how it affects damage tolerance is essential to identify and avoid potential “cliff-edges” in future materials performance.

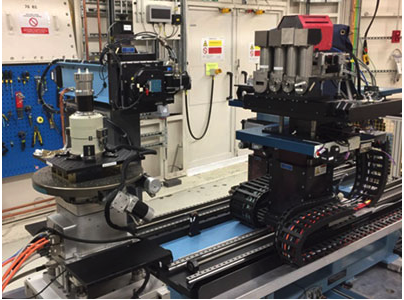

Testing is based in house and using the Diamond Light Source synchrotron x-ray facility at Harwell. The range of materials studied is quite remarkable; from graphite and ceramic composites for nuclear energy to interfacially-toughened polymer composite laminates for aerospace; from the study of eggs shells to samples of human bone. With experiments running from a few hours to several days, it does not come as a surprise to learn that the CT facility is running 24/7. The micro CT system is a ZEISS Xradia 510 Versa. This provides a two-stage magnification technique to enable high resolution at a distance (RaaD). In the first stage, the sample image is enlarged through geometric magnification as with conventional micro-CT. In the second stage, a scintillator converts X-rays to visible light, which is then optically magnified. Reducing dependence upon geometric magnification enables the Versa to maintain submicron resolution at large working distances, which is essential for in situ observations of mechanical testing.

The figure shows a silicon-carbide ceramic composite that is designed for future accident tolerant nuclear fuels. In situ mechanical loading has been applied to create an internal pressure, which eventually initiates cracks from the larger pores within its woven structure. The digital volume correlation analysis of the tomographs reveals cracks as strains (colour), and the sequence and pattern of their nucleation and growth is used to test high fidelity models that predict how changes in microstructure affect the structural integrity of the material.1,2

The Deben Microtest CT tensile stages for µXCT systems allow samples to be examined using customised load cells in the range from 150 N up to 5000 N (5kN). Custom versions are available with Peltier heating & cooling from -20 °C to +160 °C, extended stroke and travel.

Media Partners