Channels

Special Offers & Promotions

JPK Selects Compact Tensile Stage from Deben for their NanoWizard AFM Platform to Broaden Capabilities for Materials Characterisation

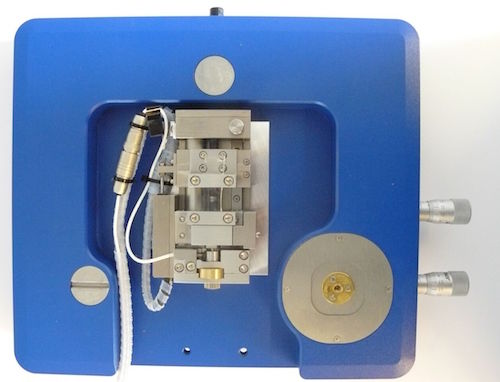

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, have supplied leading German instrument manufacturers, JPK Instruments, with a tensile stage to use in conjunction with the world-renowned NanoWizard® AFM platform.

Dr Torsten Mueller is a member of the development team with German nanoscience instrument makers, JPK Instruments. Dr Mueller and his colleagues are based in Berlin supporting a worldwide user network which is continuously testing JPK with requests for new capabilities for their life science and materials nanoscience systems. The main product is the NanoWizard® AFM platform for which JPK are seeing more and more demands to measure the materials mechanical properties. For example, there is a need to compare the bulk Young's modulus of materials used in life sciences and biomaterial research (e.g. hydrogels, composites like parafilm, materials with deposited extracellular matrix protein like collagen) with data obtained by atomic force microscopy, AFM, which characterizes the local, static and dynamic E-modulus distribution. The next step was to find a suitable micro stretching device that would fit under the AFM head under top view access to enable better correlation in time and space. This would then enable simultaneous nanomechanical and topographic studies of samples under strain.

Dr Mueller describes the reasoning why JPK chose the tensile stage from Deben (Microtest 200N). “We decided to go with Deben for a number of reasons. Firstly, it allows us to work simultaneously with our tip-scanning AFM and simultaneous top view observation. Secondly, the bi-directional stretching operation means the centre region of the sample will stay in position related to the optical axes and the adjusted AFM cantilever. We also find the height and overall size of the stretching stage allows us to mount it on our base stage providing the flexibility either as a stand–alone system or to use on top of an optical microscope body. And not least, it comes at a fair price.”

In a comprehensive series of tests and comparisons with other suppliers, JPK found the Deben stage enabled successful imaging, force-spectroscopy and force mapping and Quantitative Imaging, QI™, under non- and strained conditions. Now offered by JPK as the “Stretching Stage,” it provides the ability to study a broad range of samples to observe and quantify the influence of compression and stretching on the nanometre scale. The stage houses an interchangeable load cell offering flexibility in the force range. The standard load cell has a maximum force of 200N with an accuracy of +/- 1%. This means that with careful sample preparation, the uniaxial stress range that can be reliably applied runs from a few tens of kPa to a few GPa. Experiments can be performed with fixed strain, strain rate or applied stress. The resultant data can be plotted in real time with the corresponding AFM measurements.

more news from JPK instruments

Media Partners