Channels

Special Offers & Promotions

Deben Announce that their Tensile Stage has been Selected by GETec & Nanosurf for their AFSEM Correlative AFM and SEM Product

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, reports on the use of the AFSEM™ correlative AFM & SEM system with their tensile stage for in situ mechanical test and measurement.

Manufactured by GETec, it will be sold by Nanosurf and other selected sales channels worldwide.

Manufactured by GETec, it will be sold by Nanosurf and other selected sales channels worldwide.

The combination of complementary techniques is a key success factor for gaining new insights into the micro and nano worlds. AFSEM™ enables users to easily combine two of the most powerful analytical techniques available — AFM and SEM — to greatly extend their correlative microscopy and analysis possibilities. Austrian instrument company, GETec Microscopy GmbH, has developed AFSEM™ — a high-end atomic force microscope (AFM) for seamless integration into most of the commercially available scanning electron microscopes (SEM and SEM/FIB). The new system combines the benefits of SEM and AFM into one instrument, providing unique options for users. These include the abilities to make tensile, indentation and electrical measurements, all on the nanoscale.

The detailed study of material fracture surfaces is routinely used to address the cause of failure in engineering structures. At the nanoscale, it is a main research area in material science to develop and evaluate theoretical models of crack growth behaviour. The scanning electron microscope (SEM) is a powerful tool to study the surface changes and fracture mechanics of tensile stress samples. The combination of a large field of view with nanometer resolution allows detecting the early stages of crack or fracture formation, sample deformation, breakage analysis and other surface defects like changes in roughness. However, quantitative height information and crack/roughness analysis with sub-nanometer resolution is not possible with the SEM.

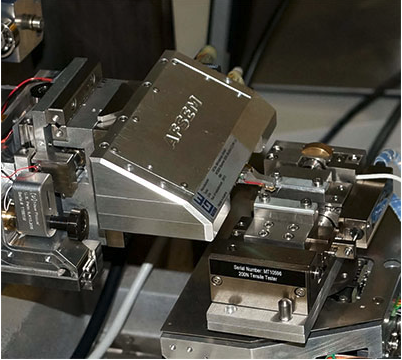

GETec selected the Deben Microtest 200N tensile stage based on the experience demonstrated by Deben over many years of supplying stages to users of electron microscopes worldwide. Load cells from 2N to 200N cover most applications, employing extension rates from 0.1mm/min to 15mm/min. The stage has a linear scale for elongation measurement and optical encoders for speed control. Samples are mounted horizontally, clamped to a pair of jaws and supported on stainless steel sliding bearings. A dual threaded leadscrew drives the jaws symmetrically in opposite directions, keeping the sample centred in the field of view. Options include three and four point bending clamps, fibre clamps and microscope mounting adaptors. All modules are controlled from Deben's Microtest tensile testing software and special versions can be manufactured to customers' requirements.

Combining the Microtest tensile stage with AFSEM provides correlative in situ analysis of the tensile properties of samples. As AFSEM is a tip-scanning AFM, it does not interfere with the operation of the tensile stage. This means the tensile stage carrying the sample can be accessed in an interactive manner allowing a stepwise increase of tensile stress with consecutive analysis without the need to vent the SEM and take out the sample for each AFM scan and analysis.

The use of the combined system has been well demonstrated with the study of a copper wire. The tensile force was measured as a function of the wire’s length during 500 µm step increments. As the wire was stretched, images of surface roughness were recorded using the both the SEM and the AFM. (see images attached below).

In summary, combining the Deben tensile stage with the AFSEM™ provides users with the solution to obtain detailed correlative information of the smallest surface changes and quantitative data on crack formation or crack growth, roughness increase, or any other material deformation as a function of tensile stress. The SEM allows guiding the AFM to the regions of interest, e.g. to image areas of constrictions or with increasing number of cracks while the tensile stage provides the application of controlled stress.

Media Partners