Channels

Special Offers & Promotions

Fleming PTC and Malvern Instruments unique approach accelerates co-extrusion process development

Recent polymer co-extrusion studies demonstrate the value of a unique die developed by Fleming Polymer Testing and Consultancy, for use with the Rosand capillary rheometer from Malvern Instruments. In combination the die and rheometer generate all the data needed to develop and validate co-extrusion process models, reducing the need for pilot scale studies. Small-scale experimentation coupled with process modelling gives detailed insight and reduces the time and expense associated with process optimization.

Recent polymer co-extrusion studies demonstrate the value of a unique die developed by Fleming Polymer Testing and Consultancy, for use with the Rosand capillary rheometer from Malvern Instruments. In combination the die and rheometer generate all the data needed to develop and validate co-extrusion process models, reducing the need for pilot scale studies. Small-scale experimentation coupled with process modelling gives detailed insight and reduces the time and expense associated with process optimization.

Polymers are co-extruded to form composite products that exploit the properties of different materials. A prime example is multi-layer films which incorporate different materials to individually impart properties such as strength, printability, permeability. The development of successful co-extrusion systems demands careful control and matching of the constituent polymers, ideally at an early stage of the development process. Research shows that good rheological data allow highly effective simulation of co-extrusion processes, providing models for system optimisation.

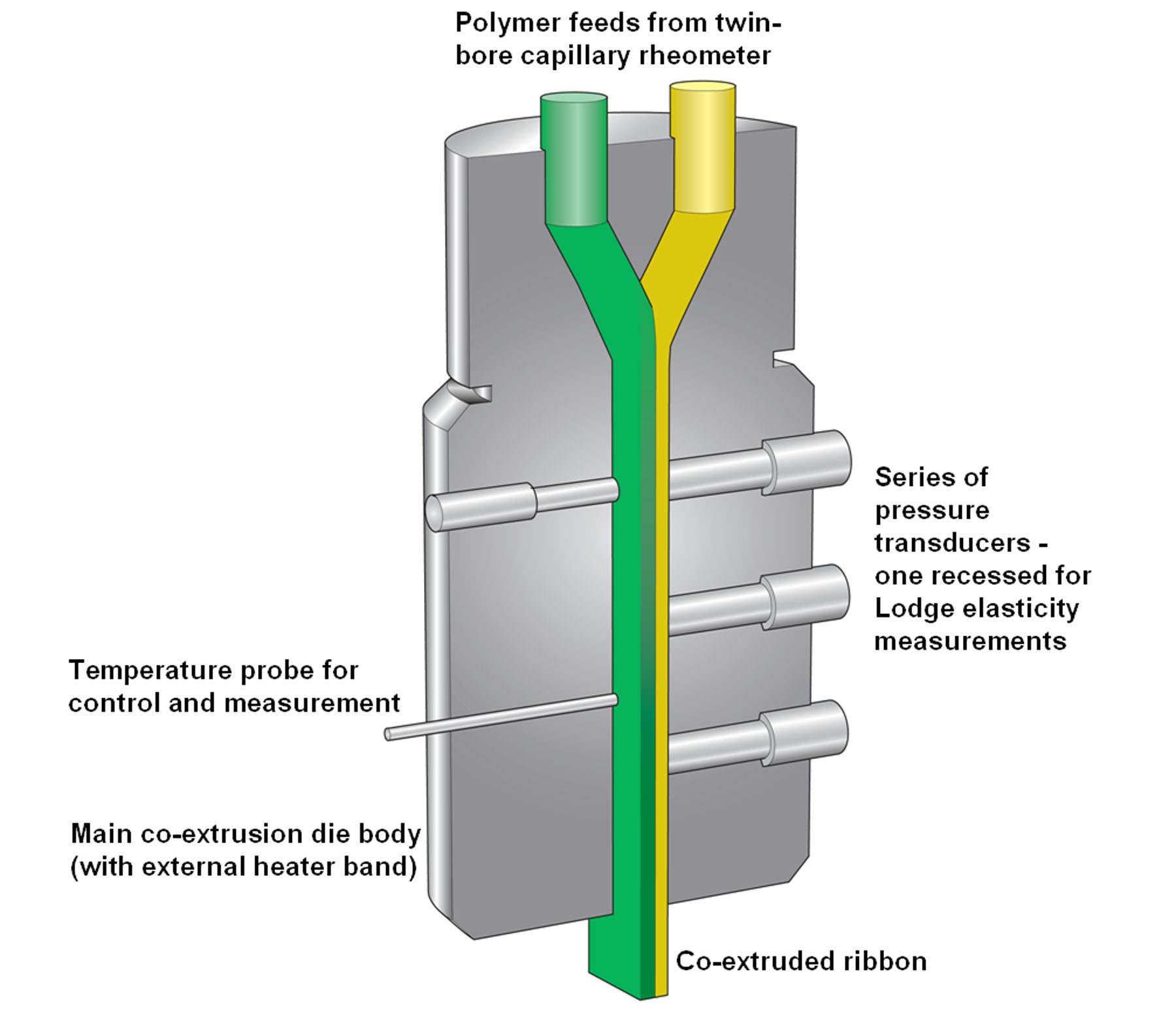

The Fleming PTC die exploits the design features of the Rosand rheometer to provide an integrated solution for the small scale study of co-extrusion behaviour. Accurate measurement of the pressure drop across the flow channel, at controlled polymer flow rates and temperature, produces the shear stress, shear rate and shear viscosity data needed for modelling. The geometry of the die can be altered to manipulate shear rates using a series of inserts. The position of the resulting interface in a two-polymer system can be determined both by visual examination of the samples produced and prediction via flow simulation. In this way, the predicted interface position can be validated by practical observation together with assessment of the physical compatibility of the two polymers being coextruded.

A model that accurately describes the co-extrusion process is an extremely valuable tool for full-scale process optimization. It can be used to target and reduce pilot studies, cutting development time and expenditure.

To download details of the system, and an experimental study, visit http://www.malvern.com/coextrusion

To find out more about Malvern rheology products see http://www.malvern.com/rheometers

For more about Fleming Polymer Testing and Consultancy go to http://www.flemingptc.co.uk/

Media Partners