Channels

Special Offers & Promotions

Freeman Technology

Products

Contact Freeman Technology

All articles from Freeman Technology

Powder Characterisation Workshop Hosted by Freeman Technology and Surface Measurement Systems

Apr 5, 2017

Freeman Technology Launches a New Ground-Breaking Powder Tester for Cost-Efficient Industrial Measurement

Jan 19, 2016

New Data Underlines the Value of the FT4 Powder Rheometer for Roller Compaction Process Optimisation

Nov 16, 2015

Freeman Technology Appoints a New Distributor for Scandinavia as Installations Hit an all Time High

Jun 9, 2015

New Research Highlights the Value of Powder Testing in Developing Continuous Tableting Processes

Feb 19, 2015

Freeman Technology Launches New Website with Extensive Knowledge Base for Powder Processors

Jul 2, 2014

Freeman Technology Speakers to Present Four Papers at 7th World Congress on Particle Technology

Apr 29, 2014

Freeman Technology highlights the FT4 Powder Rheometer for process development at Interphex 2014

Mar 10, 2014

Freeman Technology and GEA Pharma Systems collaborate to advance continuous manufacturing for pharma

Jan 28, 2014

LPW Technology invests in FT4 Powder Rheometer to optimise metal powders for additive manufacture

Jan 14, 2014

Freeman Technology will present new research on the impact of humidity on powders at Powtech 2013

Feb 21, 2013

University of Bath PhD student wins Powder Flow 2011 poster prize sponsored by Freeman Technology

Dec 14, 2011

Freeman Technology presents new work at AAPS 2011 on measuring meaningful powder flow properties

Sep 29, 2011

Less noise, cleaner data: FT4 Powder Rheometer proves critical to modelling studies at RCPE Graz

Jul 13, 2011

Freeman Technology to present poster on wet granulation at the International Granulation Conference 2011

Jun 8, 2011

Freeman Technology director to speak on powder characterisation at Bulk Solids India 2011 in Mumbai

Mar 8, 2011

On show at DDL21 - FT4 Powder Rheometer provides unique insight for dry powder inhalers

Nov 30, 2010

Media Partners

A new eBook from Freeman Technology, a Micromeritics company and global leader in powder characterisation, explores the application of powder flow measurements for monitoring and optimising granulation processes. Granulation is a vital unit operation for many industries, notably the pharmaceutical sector, but endpoint detection and scale-up remain a challenge. ‘Powder Flow Testing for Granulation Processes’ focuses on the value of bulk powder characterisation...

A new eBook from Freeman Technology, a Micromeritics company and global leader in powder characterisation, explores the application of powder flow measurements for monitoring and optimising granulation processes. Granulation is a vital unit operation for many industries, notably the pharmaceutical sector, but endpoint detection and scale-up remain a challenge. ‘Powder Flow Testing for Granulation Processes’ focuses on the value of bulk powder characterisation... The new website from Freeman Technology (Tewkesbury, UK), a Micromeritics company and the global leaders in powder characterisation technology, is a clear, easy-to-navigate resource that covers all aspects of powder testing in unrivalled breadth and depth. Showcasing the company’s library of new videos, it includes a wealth of content from animations and online presentations to detailed customer stories and e-books....

The new website from Freeman Technology (Tewkesbury, UK), a Micromeritics company and the global leaders in powder characterisation technology, is a clear, easy-to-navigate resource that covers all aspects of powder testing in unrivalled breadth and depth. Showcasing the company’s library of new videos, it includes a wealth of content from animations and online presentations to detailed customer stories and e-books.... Recent revisions of two popular e-books from Freeman Technology offer clear, expert advice for those looking to invest in powder testing technology. ‘Choosing a Powder Tester’ reviews the technology available and has been updated to include recent innovations such as uniaxial powder testing. ‘The Value of Powder Testing’ considers how test data deliver an economic return and now extends to assessment of the benefits of real-time measurement...

Recent revisions of two popular e-books from Freeman Technology offer clear, expert advice for those looking to invest in powder testing technology. ‘Choosing a Powder Tester’ reviews the technology available and has been updated to include recent innovations such as uniaxial powder testing. ‘The Value of Powder Testing’ considers how test data deliver an economic return and now extends to assessment of the benefits of real-time measurement... Micromeritics Instrument Corporation, a leading global manufacturer of premium products for advanced material characterisation, has announced the acquisition of Freeman Technology. Freeman Technology specialises in providing instruments for the measurement of powder flow properties and other behavioural properties of powders...

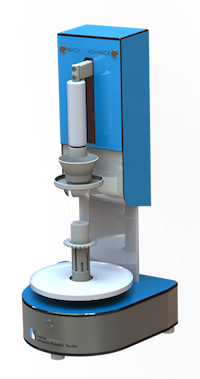

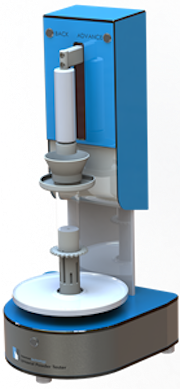

Micromeritics Instrument Corporation, a leading global manufacturer of premium products for advanced material characterisation, has announced the acquisition of Freeman Technology. Freeman Technology specialises in providing instruments for the measurement of powder flow properties and other behavioural properties of powders... A key part of any powder process is understanding how powders behave when subjected to consolidation. It is crucial for the development of effective storage and processing strategies. The Uniaxial Powder Tester, from Freeman Technology, is a stand-alone shear tester for simple, sensitive and cost-effective powder characterisation....

A key part of any powder process is understanding how powders behave when subjected to consolidation. It is crucial for the development of effective storage and processing strategies. The Uniaxial Powder Tester, from Freeman Technology, is a stand-alone shear tester for simple, sensitive and cost-effective powder characterisation.... Powder characterisation specialists, Freeman Technology, will be presenting at the upcoming ACHEMA exhibition and congress (11-15 June 2018, Frankfurt, Germany). Delegates will have the opportunity to hear from members of the Freeman team throughout the congress; where topics include predicting screw feeder performance (12 June at 15:00), the influence of fines content on the flow behaviour of FCC catalysts (13 June at 16:20)...

Powder characterisation specialists, Freeman Technology, will be presenting at the upcoming ACHEMA exhibition and congress (11-15 June 2018, Frankfurt, Germany). Delegates will have the opportunity to hear from members of the Freeman team throughout the congress; where topics include predicting screw feeder performance (12 June at 15:00), the influence of fines content on the flow behaviour of FCC catalysts (13 June at 16:20)... Powders play an integral part in the production of many products and it is widely acknowledged that they are challenging to handle. It is therefore vital for engineers and processors to have a good understanding of powder behaviour in order to optimise productivity and improve quality. This is particularly applicable in powder metallurgy, where the flowability of metal powders is crucial to efficiency, including...

Powders play an integral part in the production of many products and it is widely acknowledged that they are challenging to handle. It is therefore vital for engineers and processors to have a good understanding of powder behaviour in order to optimise productivity and improve quality. This is particularly applicable in powder metallurgy, where the flowability of metal powders is crucial to efficiency, including...

“We have been working with businesses in Germany since the company was founded. “It has long been a region with a significant number of powder processing companies across a range of industries” said Tim Freeman, Managing Director....

“We have been working with businesses in Germany since the company was founded. “It has long been a region with a significant number of powder processing companies across a range of industries” said Tim Freeman, Managing Director.... Based in Kobe City, Mr Nishimura has over 10 years of experience working in the analytical instrumentation industry and will provide sales and customer support in the region....

Based in Kobe City, Mr Nishimura has over 10 years of experience working in the analytical instrumentation industry and will provide sales and customer support in the region.... The company offers material characterisation solutions aimed at optimising process performance, increasing productivity and improving quality in a diverse range of sectors, including powder coatings. Freeman Technology’s solutions include the FT4 Powder Rheometer®, a unique and comprehensive powder tester, which uses patented dynamic methodology, automated shear cells...

The company offers material characterisation solutions aimed at optimising process performance, increasing productivity and improving quality in a diverse range of sectors, including powder coatings. Freeman Technology’s solutions include the FT4 Powder Rheometer®, a unique and comprehensive powder tester, which uses patented dynamic methodology, automated shear cells... Freeman now has global distribution rights for Lenterra products. Freeman’s application expertise, in combination with Lenterra’s technology, offers valuable new opportunities for comprehensive powder characterisation and process optimisation. “Moving into inline monitoring of both batch and continuous processes is a logical step for us as we strengthen and diversify our offering to meet industrial requirements,” said Tim Freeman, Managing Director of Freeman...

Freeman now has global distribution rights for Lenterra products. Freeman’s application expertise, in combination with Lenterra’s technology, offers valuable new opportunities for comprehensive powder characterisation and process optimisation. “Moving into inline monitoring of both batch and continuous processes is a logical step for us as we strengthen and diversify our offering to meet industrial requirements,” said Tim Freeman, Managing Director of Freeman... The new UPT was developed by Freeman Technology in collaboration with the University of Edinburgh, DuPont and The Chemours Company to offer rapid, cost-effective industrial powder testing. “For anyone familiar with powder testing, the uniaxial shear testing technique is a well-known concept,” said Jamie Clayton, Operations Director for Freeman Technology. “While its potential advantages have long been recognised, the practicalities of measurement have previously...

The new UPT was developed by Freeman Technology in collaboration with the University of Edinburgh, DuPont and The Chemours Company to offer rapid, cost-effective industrial powder testing. “For anyone familiar with powder testing, the uniaxial shear testing technique is a well-known concept,” said Jamie Clayton, Operations Director for Freeman Technology. “While its potential advantages have long been recognised, the practicalities of measurement have previously... “Continued growth is, of course, highly encouraging and a tribute to the team,” said Tim Freeman, Managing Director of Freeman Technology. “New partnerships in Italy, and the Czech Republic, along with our recent expansion of the China team, underline our commitment to maintaining exemplary service across the globe, as we grow. The recent launch of the Uniaxial Powder Tester also emphasises our...

“Continued growth is, of course, highly encouraging and a tribute to the team,” said Tim Freeman, Managing Director of Freeman Technology. “New partnerships in Italy, and the Czech Republic, along with our recent expansion of the China team, underline our commitment to maintaining exemplary service across the globe, as we grow. The recent launch of the Uniaxial Powder Tester also emphasises our... The award is in recognition of the time and extensive effort in developing the ASTM Standard Designation D7891 “Standard Test Method for Shear Testing of Powders using the Freeman Technology FT4 Powder Rheometer Shear Cell”. Tim Freeman, Managing Director of Freeman Technology, said, “We are thrilled to have received this prestigious award from ASTM in recognition of our efforts. I’d like to take this...

The award is in recognition of the time and extensive effort in developing the ASTM Standard Designation D7891 “Standard Test Method for Shear Testing of Powders using the Freeman Technology FT4 Powder Rheometer Shear Cell”. Tim Freeman, Managing Director of Freeman Technology, said, “We are thrilled to have received this prestigious award from ASTM in recognition of our efforts. I’d like to take this... The new powder tester provides an accurate and repeatable measure of the unconfined yield strength (UYS) of a powder to assess and rank flowability. It is quick, reliable and easy to use, delivering value to scientists, process engineers and QC analysts working in a diverse range of bulk solids handling industries. Available in manual and advanced versions, the UPT offers a low cost, powder testing solution. Alongside the UPT, the company continues to provide a comprehensive powder...

The new powder tester provides an accurate and repeatable measure of the unconfined yield strength (UYS) of a powder to assess and rank flowability. It is quick, reliable and easy to use, delivering value to scientists, process engineers and QC analysts working in a diverse range of bulk solids handling industries. Available in manual and advanced versions, the UPT offers a low cost, powder testing solution. Alongside the UPT, the company continues to provide a comprehensive powder... Developed in collaboration with the University of Edinburgh and a major industrial powder processor, the new tester delivers automated, highly repeatable measurement and provides a cost effective alternative to traditional powder testing techniques. It offers significant value to engineers and QC analysts working across a number of industries, from bulk solids handling to pharmaceuticals. “Uniaxial powder testing is a simple and...

Developed in collaboration with the University of Edinburgh and a major industrial powder processor, the new tester delivers automated, highly repeatable measurement and provides a cost effective alternative to traditional powder testing techniques. It offers significant value to engineers and QC analysts working across a number of industries, from bulk solids handling to pharmaceuticals. “Uniaxial powder testing is a simple and... Results from a series of collaborative experiments show that dynamic powder properties measured with the FT4 Powder Rheometer® reliably detect and quantify the effect of changing compactor operating parameters. Such correlations make it quicker and easier to establish optimal conditions for producing granules that meet defined performance targets from any given feed. Faster optimisation and responsive process control help to drive up manufacturing efficiency, even in the event of...

Results from a series of collaborative experiments show that dynamic powder properties measured with the FT4 Powder Rheometer® reliably detect and quantify the effect of changing compactor operating parameters. Such correlations make it quicker and easier to establish optimal conditions for producing granules that meet defined performance targets from any given feed. Faster optimisation and responsive process control help to drive up manufacturing efficiency, even in the event of... Through experimental study, experts from the two companies have identified easily measurable powder properties that can be used to predict screw feeder performance for any given powder. The resulting correlations support optimised feeder selection for a new powder on the basis of testing a small quantity of powder. “For Gericke AG, selecting the best screw feeder for a given powder is an essential aspect of our business, and something our customers...

Through experimental study, experts from the two companies have identified easily measurable powder properties that can be used to predict screw feeder performance for any given powder. The resulting correlations support optimised feeder selection for a new powder on the basis of testing a small quantity of powder. “For Gericke AG, selecting the best screw feeder for a given powder is an essential aspect of our business, and something our customers... The appointment follows news of a record first quarter for the company that saw more FT4 Powder Rheometer® installations than during the same period in any previous year.

The appointment follows news of a record first quarter for the company that saw more FT4 Powder Rheometer® installations than during the same period in any previous year.  Entitled, ‘Standard Test Method for Shear Testing of Powders using the Freeman Technology FT4 Powder Rheometer Shear Cell’, ASTM D7891 details the apparatus and procedures for evaluating the incipient failure properties of a powder under consolidation, including the determination of parameters such as Cohesion, Unconfined Yield Strength and Flow Function. D7891 has been published by Subcommittee D18.24 on Characterization and...

Entitled, ‘Standard Test Method for Shear Testing of Powders using the Freeman Technology FT4 Powder Rheometer Shear Cell’, ASTM D7891 details the apparatus and procedures for evaluating the incipient failure properties of a powder under consolidation, including the determination of parameters such as Cohesion, Unconfined Yield Strength and Flow Function. D7891 has been published by Subcommittee D18.24 on Characterization and... Visitors will have the opportunity to discuss their individual powder processing challenges with the Freeman Technology team on stand 4.2 L36, where they will be able to see a demonstration of the FT4 Powder Rheometer and collect a copy of ‘The Value of Powder Testing’, the third in a series of educational guides on powder characterisation. The booklet evaluates the economic benefits that can be realised by incorporating relevant powder tests into an operation. It addresses key questions such as what makes...

Visitors will have the opportunity to discuss their individual powder processing challenges with the Freeman Technology team on stand 4.2 L36, where they will be able to see a demonstration of the FT4 Powder Rheometer and collect a copy of ‘The Value of Powder Testing’, the third in a series of educational guides on powder characterisation. The booklet evaluates the economic benefits that can be realised by incorporating relevant powder tests into an operation. It addresses key questions such as what makes... The new booklet focuses on how to assess the economic benefits that a powder tester can deliver and explains how these may vary considerably depending on the instrumentation selected. All three guides, including, ‘An Introduction to Powders’ and ‘Choosing a Powder Tester’, are written in an easy to understand, straightforward style and are now available for download at http://www.freemantech.co.uk/_ebook/. The new guide addresses...

The new booklet focuses on how to assess the economic benefits that a powder tester can deliver and explains how these may vary considerably depending on the instrumentation selected. All three guides, including, ‘An Introduction to Powders’ and ‘Choosing a Powder Tester’, are written in an easy to understand, straightforward style and are now available for download at http://www.freemantech.co.uk/_ebook/. The new guide addresses... Both companies are investing significant resource in the project and it is expected to deliver further substantive results over the next quarter. Within the pharmaceutical industry the replacement of batch tablet production units with continuous manufacturing suites has the potential to significantly improve efficiency and reduce costs. Freeman Technology, a global leader in powder testing instrumentation, and GEA, a specialist provider...

Both companies are investing significant resource in the project and it is expected to deliver further substantive results over the next quarter. Within the pharmaceutical industry the replacement of batch tablet production units with continuous manufacturing suites has the potential to significantly improve efficiency and reduce costs. Freeman Technology, a global leader in powder testing instrumentation, and GEA, a specialist provider... Following on from the well received ‘An Introduction to Powders’ the new guide provides straightforward guidance on the range of techniques available for powder characterisation. Both booklets are now available to download for free from the new Freeman Technology website. Understanding powder behaviour is essential to ensuring effective product and process performance. Powder testing techniques that allow users to understand and control both the product and manufacturing process therefore deliver substantial value...

Following on from the well received ‘An Introduction to Powders’ the new guide provides straightforward guidance on the range of techniques available for powder characterisation. Both booklets are now available to download for free from the new Freeman Technology website. Understanding powder behaviour is essential to ensuring effective product and process performance. Powder testing techniques that allow users to understand and control both the product and manufacturing process therefore deliver substantial value... Based in Shanghai, Joey adds a wealth of experience to the Freeman Technology team and will manage sales and marketing activities as well as further extending support for existing users in the region. Tim Freeman, Managing Director, said, “It is an exciting time for Freeman Technology. The creation of a direct operation in China reflects the sustained growth we have seen there in recent years. The provision of a local operation allows us to...

Based in Shanghai, Joey adds a wealth of experience to the Freeman Technology team and will manage sales and marketing activities as well as further extending support for existing users in the region. Tim Freeman, Managing Director, said, “It is an exciting time for Freeman Technology. The creation of a direct operation in China reflects the sustained growth we have seen there in recent years. The provision of a local operation allows us to... The new site provides a detailed overview of the complexity of powders and the challenges they present, and uses industry specific examples to demonstrate how powder rheology has been used to solve processing problems. The website uses simple, straightforward language and introduces new videos and animations to illustrate the fundamentals of powder behaviour and the basic principles of powder testing...

The new site provides a detailed overview of the complexity of powders and the challenges they present, and uses industry specific examples to demonstrate how powder rheology has been used to solve processing problems. The website uses simple, straightforward language and introduces new videos and animations to illustrate the fundamentals of powder behaviour and the basic principles of powder testing... Written in a straightforward, easy to understand style, the new booklet explains how and why powders behave the way they do, and how this impacts powder processing and characterisation. It provides a valuable foundation for those with little prior knowledge of powders as well as being a useful resource for anyone looking to expand their understanding of the factors relevant to product development and processing performance...

Written in a straightforward, easy to understand style, the new booklet explains how and why powders behave the way they do, and how this impacts powder processing and characterisation. It provides a valuable foundation for those with little prior knowledge of powders as well as being a useful resource for anyone looking to expand their understanding of the factors relevant to product development and processing performance... Tim Freeman is an invited speaker at the Particle Design: Formulation and Processing session, where he will present ‘A QbD Approach to Continuous Tablet Manufacture’. This talk will focus on the use of powder characterisation to measure material properties that directly correlate with the quality attributes of a finished product to support the development of continuous processes...

Tim Freeman is an invited speaker at the Particle Design: Formulation and Processing session, where he will present ‘A QbD Approach to Continuous Tablet Manufacture’. This talk will focus on the use of powder characterisation to measure material properties that directly correlate with the quality attributes of a finished product to support the development of continuous processes... Freeman Technology’s US team will be showcasing the capabilities of the FT4 Powder Rheometer® at the PTXi/Powder & Bulk Solids show in Rosemont IL, from 6-8 May 2014. At the same time Operations Director Jamie Clayton is an invited speaker on the ‘Analytical Methods for Powder Handling and Processing’ course organised by Powder Info News in Copenhagen on 6 May....

Freeman Technology’s US team will be showcasing the capabilities of the FT4 Powder Rheometer® at the PTXi/Powder & Bulk Solids show in Rosemont IL, from 6-8 May 2014. At the same time Operations Director Jamie Clayton is an invited speaker on the ‘Analytical Methods for Powder Handling and Processing’ course organised by Powder Info News in Copenhagen on 6 May....

The work involves Freeman Technology’s FT4 Powder Rheometer® and GEA Pharma Systems’ ConsiGma™ 1 continuous granulation unit. Data from the FT4 are being used to quantify the influence of the operating conditions of the ConsiGma1 on the bulk characteristics of the granules being manufactured. These data are then correlated to attributes of the tablets, providing the link between granule and tablet properties.....

The work involves Freeman Technology’s FT4 Powder Rheometer® and GEA Pharma Systems’ ConsiGma™ 1 continuous granulation unit. Data from the FT4 are being used to quantify the influence of the operating conditions of the ConsiGma1 on the bulk characteristics of the granules being manufactured. These data are then correlated to attributes of the tablets, providing the link between granule and tablet properties.....

The course will help attendees to develop a better understanding of powder behaviour, of the tools available for powder characterisation, and of modern processing technology. It is suitable for those working in academia or industry, in R&D or production. Tim Freeman’s lecture will look at the basics of powder behaviour, focusing especially on powder flowability which has a defining influence on the efficiency of many processes....

The course will help attendees to develop a better understanding of powder behaviour, of the tools available for powder characterisation, and of modern processing technology. It is suitable for those working in academia or industry, in R&D or production. Tim Freeman’s lecture will look at the basics of powder behaviour, focusing especially on powder flowability which has a defining influence on the efficiency of many processes.... Freeman Technology specialises in instruments for measuring the flow properties of powders. Last year the company appointed DKSH as its distribution partner in China and also made the first sales of its universal powder tester, the FT4 Powder Rheometer®, in this market. DKSH is the world’s largest Market Expansion Services provider with a focus on Asia....

Freeman Technology specialises in instruments for measuring the flow properties of powders. Last year the company appointed DKSH as its distribution partner in China and also made the first sales of its universal powder tester, the FT4 Powder Rheometer®, in this market. DKSH is the world’s largest Market Expansion Services provider with a focus on Asia.... The presentation, entitled ‘The influence of ambient moisture on powder flow’, will be the first opportunity to learn about the company’s latest study highlighting how the FT4 Powder Rheometer® can be used to quantify the impact of humidity in a process relevant way. The team will also present two posters entitled “Investigation of the influence of atomic layer deposition coatings on powder rheology” and “Quantifying the effect of caking by powder rheometry”...

The presentation, entitled ‘The influence of ambient moisture on powder flow’, will be the first opportunity to learn about the company’s latest study highlighting how the FT4 Powder Rheometer® can be used to quantify the impact of humidity in a process relevant way. The team will also present two posters entitled “Investigation of the influence of atomic layer deposition coatings on powder rheology” and “Quantifying the effect of caking by powder rheometry”... Visitors to the symposium will also have the opportunity to investigate Freeman Technology's FT4 Powder Rheometer on the DKSH exhibition booth. Both of Tim Freeman's papers will present the benefits of better data for more informed powder handling in manufacturing processes. The first will focus on how to evaluate the effect of vibration-induced powder compaction through flow property measurement and the second will look at the influence of powder flow properties on the filling of dies and capsules...

Visitors to the symposium will also have the opportunity to investigate Freeman Technology's FT4 Powder Rheometer on the DKSH exhibition booth. Both of Tim Freeman's papers will present the benefits of better data for more informed powder handling in manufacturing processes. The first will focus on how to evaluate the effect of vibration-induced powder compaction through flow property measurement and the second will look at the influence of powder flow properties on the filling of dies and capsules... Quantifying the impact of humidity on powder properties' by Brian Armstrong (Powder Technologist) and Jamie Clayton (Operations Manager), Freeman Technology, is now available for download...

Quantifying the impact of humidity on powder properties' by Brian Armstrong (Powder Technologist) and Jamie Clayton (Operations Manager), Freeman Technology, is now available for download... Powder characterisation company Freeman Technology is exhibiting the company's universal powder tester, the FT4 Powder Rheometer, at ACHEMA 2012 (Frankfurt, Germany; 18-22 June 2012), and members of the team will be speaking at congress sessions.

Powder characterisation company Freeman Technology is exhibiting the company's universal powder tester, the FT4 Powder Rheometer, at ACHEMA 2012 (Frankfurt, Germany; 18-22 June 2012), and members of the team will be speaking at congress sessions. Powder characterisation specialist Freeman Technology is delighted to announce that the company is to receive the 2012 Queen's Award for Enterprise in the category International Trade. Recognised around the world, the Queen's Awards for Enterprise are Britain's most coveted commercial prizes and this appreciation of Freeman Technology's rapidly growing international presence follows the company's 2007 Queen's Award in the category of Innovation...

Powder characterisation specialist Freeman Technology is delighted to announce that the company is to receive the 2012 Queen's Award for Enterprise in the category International Trade. Recognised around the world, the Queen's Awards for Enterprise are Britain's most coveted commercial prizes and this appreciation of Freeman Technology's rapidly growing international presence follows the company's 2007 Queen's Award in the category of Innovation... Building on a decade of successful business in North America, powder characterisation specialist Freeman Technology is pleased to announce that in January 2012 the company formally established a US subsidiary, Freeman Technology Inc. This new organisation will take on responsibility for sales, service and applications support for the ever growing number of FT4 Powder Rheometer users in the US, and will work with prospective customers across all industrial markets...

Building on a decade of successful business in North America, powder characterisation specialist Freeman Technology is pleased to announce that in January 2012 the company formally established a US subsidiary, Freeman Technology Inc. This new organisation will take on responsibility for sales, service and applications support for the ever growing number of FT4 Powder Rheometer users in the US, and will work with prospective customers across all industrial markets... At AZO GmbH + Co. KG (Osterburken, Germany), one of the world's leading suppliers of automated raw material handling equipment, the introduction of the FT4 Powder Rheometer has revolutionised the company's approach to powder characterisation. Replacing older shear cell equipment and a basic powder tester, use of the FT4 has dramatically reduced the time taken to reliably characterise a new powder and enhanced AZO's ability to design and specify optimised solutions uniquely tailored to individual customer needs...

At AZO GmbH + Co. KG (Osterburken, Germany), one of the world's leading suppliers of automated raw material handling equipment, the introduction of the FT4 Powder Rheometer has revolutionised the company's approach to powder characterisation. Replacing older shear cell equipment and a basic powder tester, use of the FT4 has dramatically reduced the time taken to reliably characterise a new powder and enhanced AZO's ability to design and specify optimised solutions uniquely tailored to individual customer needs... As well as exhibiting the FT4 Powder Rheometer at this year's AAPS Annual Meeting & Exposition (24-27 October 2011; Washington DC), Freeman Technology will present a poster detailing a comparison of dynamic powder characterisation with traditional tapped density methods for assessing powder flowability...

As well as exhibiting the FT4 Powder Rheometer at this year's AAPS Annual Meeting & Exposition (24-27 October 2011; Washington DC), Freeman Technology will present a poster detailing a comparison of dynamic powder characterisation with traditional tapped density methods for assessing powder flowability... Continuing global success has encouraged powder characterisation company Freeman Technology to relocate into new larger premises based in Tewkesbury, Gloucestershire (UK). The brand new 6,000 sq ft global HQ has been fitted out to meet the company's exact requirements for more manufacturing and office space, as well as housing an impressive 300 sq ft applications laboratory...

Continuing global success has encouraged powder characterisation company Freeman Technology to relocate into new larger premises based in Tewkesbury, Gloucestershire (UK). The brand new 6,000 sq ft global HQ has been fitted out to meet the company's exact requirements for more manufacturing and office space, as well as housing an impressive 300 sq ft applications laboratory... Researchers at the RCPE (Research Center Pharmaceutical Engineering) in Graz, Austria, are finding the reproducibility of the FT4 Powder Rheometer from Freeman Technology crucial to the success of their work on modelling powder behaviours. The RCPE is a unique internationally operating European research institute in the area of pharmaceutical process and product development, and a focal point for rational and science-based development of novel pharmaceutical drug products, as well as their manufacturing processes...

Researchers at the RCPE (Research Center Pharmaceutical Engineering) in Graz, Austria, are finding the reproducibility of the FT4 Powder Rheometer from Freeman Technology crucial to the success of their work on modelling powder behaviours. The RCPE is a unique internationally operating European research institute in the area of pharmaceutical process and product development, and a focal point for rational and science-based development of novel pharmaceutical drug products, as well as their manufacturing processes... Powder characterisation company Freeman Technology is significantly expanding its activities in Asia with the appointment of distribution partners in the region who will sell and support the company's FT4 Powder Rheometer...

Powder characterisation company Freeman Technology is significantly expanding its activities in Asia with the appointment of distribution partners in the region who will sell and support the company's FT4 Powder Rheometer... Visitors to the ‘Characterisation Instrumentation for Formulation' seminar and workshop in Huddersfield (UK) on 9 May 2011 will have the opportunity to learn how Freeman Technology's FT4 Powder Rheometer supports modern formulation goals. The aim of the event, which is organised by Intelligent Formulation Ltd, is to highlight the range of characterisation techniques available, with demonstrations from leading instrumentation manufacturers...

Visitors to the ‘Characterisation Instrumentation for Formulation' seminar and workshop in Huddersfield (UK) on 9 May 2011 will have the opportunity to learn how Freeman Technology's FT4 Powder Rheometer supports modern formulation goals. The aim of the event, which is organised by Intelligent Formulation Ltd, is to highlight the range of characterisation techniques available, with demonstrations from leading instrumentation manufacturers... Tim Freeman, Director of Operations for powder characterisation company Freeman Technology, will deliver two presentations at Bulk Solids India 2011 (6 - 9 April, Mumbai). These will cover the use of automated instrumentation in powder characterisation and the benefits such technology can bring to the powder processing industries. Newcomers to this conference, Freeman Technology will also be exhibiting...

Tim Freeman, Director of Operations for powder characterisation company Freeman Technology, will deliver two presentations at Bulk Solids India 2011 (6 - 9 April, Mumbai). These will cover the use of automated instrumentation in powder characterisation and the benefits such technology can bring to the powder processing industries. Newcomers to this conference, Freeman Technology will also be exhibiting... The new graphical user interface (GUI) for Freeman Technology's FT4 Powder Rheometer will be on show at Interphex 2011 (29-31 March 2011, New York). Flexible and intuitive, with an enhanced real-time data display, the new GUI enables all FT4 users, whether new to the system or experienced with it, to fully exploit its multi-functionality. The new software is being supplied with all new instruments and offered as a free upgrade to existing FT4 users.

The new graphical user interface (GUI) for Freeman Technology's FT4 Powder Rheometer will be on show at Interphex 2011 (29-31 March 2011, New York). Flexible and intuitive, with an enhanced real-time data display, the new GUI enables all FT4 users, whether new to the system or experienced with it, to fully exploit its multi-functionality. The new software is being supplied with all new instruments and offered as a free upgrade to existing FT4 users. Freeman Technology has added a uniaxial powder tester to the FT4 Powder Rheometer, extending the system's ability to efficiently and reproducibly measure properties that directly correlate with a powder's in-process behaviour. Uniaxial testing complements the FT4's existing test methodologies for shear, bulk and dynamic powder measurement.

Freeman Technology has added a uniaxial powder tester to the FT4 Powder Rheometer, extending the system's ability to efficiently and reproducibly measure properties that directly correlate with a powder's in-process behaviour. Uniaxial testing complements the FT4's existing test methodologies for shear, bulk and dynamic powder measurement. Just a few places are left for Freeman Technology's complimentary half day seminar on powder characterization which is being held in Mumbai, India on December 2nd 2010. Freeman Technology will showcase applications of the company's FT4 Powder Rheometer and the seminar is suitable for all those working with powders, whether in R&D, Processing, Technical Service or QC.

Just a few places are left for Freeman Technology's complimentary half day seminar on powder characterization which is being held in Mumbai, India on December 2nd 2010. Freeman Technology will showcase applications of the company's FT4 Powder Rheometer and the seminar is suitable for all those working with powders, whether in R&D, Processing, Technical Service or QC. Freeman Technology will launch a uniaxial testing solution for the company's FT4 Powder Rheometer at this year's AAPS Annual Meeting & Exposition (14-18 Nov 2010, New Orleans). The uniaxial tester further extends the FT4's ability to efficiently and reproducibly measure properties that directly correlate with a powder's in-process behaviour. Uniaxial testing complements existing test methodologies for shear, bulk and dynamic powder measurement

Freeman Technology will launch a uniaxial testing solution for the company's FT4 Powder Rheometer at this year's AAPS Annual Meeting & Exposition (14-18 Nov 2010, New Orleans). The uniaxial tester further extends the FT4's ability to efficiently and reproducibly measure properties that directly correlate with a powder's in-process behaviour. Uniaxial testing complements existing test methodologies for shear, bulk and dynamic powder measurement