Channels

Special Offers & Promotions

Schlenk Line Application Note & Vacuum Guide

Background

A Schlenk Line is a tubular glass apparatus commonly used in chemistry or material laboratory research to carry out experiments under a vacuum and an inert atmosphere (like nitrogen or argon). It is used when samples are sensitive to air/moisture and the vacuum is also often used to remove the last traces of solvent from a sample.

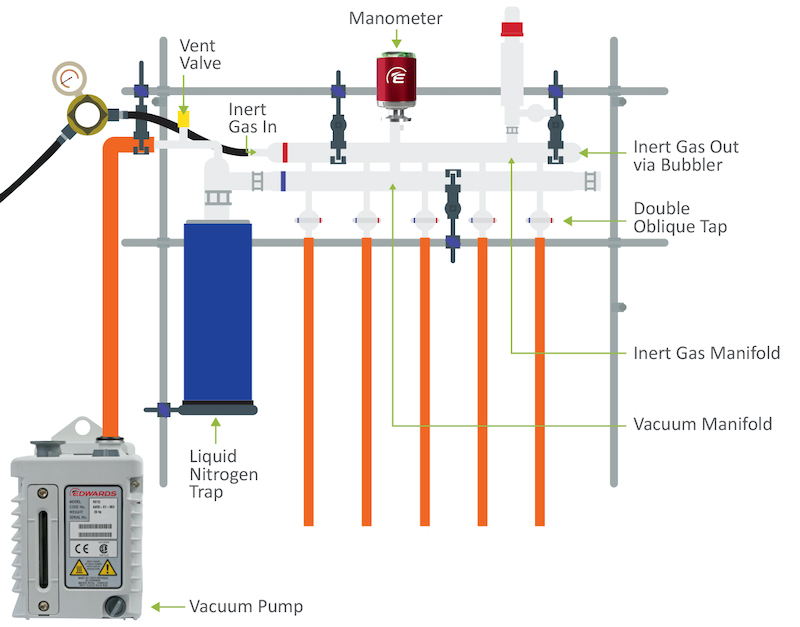

A Schlenk Line typically contains a dual glass manifold with multiple ports; the number of ports is configurable. One manifold is connected to an inert gas source, while the other one is connected to a vacuum pump (see Figure 1). A vessel with the sample is connected to the manifold e.g. by a rubber vacuum tube with each port access controlled by a tap. One backing line of the Schlenk manifold is always kept under vacuum, the other one under inert gas, controlled by valves. A cold trap of liquid nitrogen or dry ice/acetone is used between the Schlenk Line and the vacuum pump to protect the pump e.g. from the solvents which are present in the experiment. The typical vacuum pressure can go down to 1x10-3 mbar.

Challenges

Pumping condensable vapour from the process as well as the potential for corrosive or aggressive gases/vapours.

Solution

Small fore vacuum pump with a typical size of 3 to 12 m³/h. nXDS (dry scroll vacuum pumps) and RV (oil sealed rotary vane vacuum pumps) could be used for this application.

For RV versions: The robust RV pumps can be operated in the unique high throughput mode and with inert gas ballast to avoid condensation of vapours and dilute solvents entering the pump. An installed cold trap in the vacuum line, which is often already part of the Schlenk Line, captures most condensable vapours and minimizes vapours entering the vacuum pump. The installation of an EMF filter safely protects the working environment if the pump is not being used inside a fume cupboard.

For nXDS pumps: The dry running nXDS vacuum pumps should be operated with inert gas ballast to avoid condensation of vapours and dilute solvents entering the pump. C-versions should be used if slightly corrosive or aggressive gases/vapours are to be pumped. In addition, a cold trap which is often already part of the Schlenk Line, could further protect the pump.

Main benefits/Novel step

For RV versions: Well-proven solution in Schlenk Line applications. Cost-effective basic solution with efficient performance/price ratio. Long maintenance intervals because of excellent vapour handling and good capability to handle slightly corrosive or aggressive gases.

For nXDS pumps: Well-proven solution in Schlenk Line applications. No oil contamination risk because of dry technology; no oil to be contaminated by process gases. Long maintenance intervals because of excellent vapour handling. High up-time because of good capability to handle slightly corrosive or aggressive gases/vapours with special C-versions.

Vacuum Guide – Understanding the basics: Free download

When you are working with vacuum, you should first understand the basics. This begins by exploring their foundations and developing an understanding of the core concepts and terminology used in the realm of vacuum. This is the starting point for our guide.

From there, pump technologies, vacuum measurement and leak detection are discussed. Through pump sizing principles and insights into factors such as handling vapours, flammables & explosives, using gas ballast or condensers, you will get a deeper understanding of other essential principles, enabling you to make the right choices when using vacuum. This 80+ page guide a vacuum reference document which you do not want to miss out on.

Download | View free vacuum guide

Media Partners