Members Login

Channels

Special Offers & Promotions

Phenom-World Selects Deben to Supply a Tensile Stage as an Accessory to their Range of Desktop SEMs

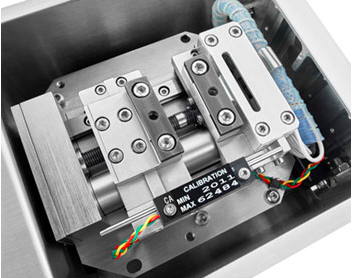

Deben, a leading provider of in-situ testing stages together with innovative accessories and components for electron microscopy, has been chosen by Phenom-World to supply the Microtest Tensile Stage as an accessory to their Phenom XL range of desktop scanning electron microscopes.

Phenom-World, the leading global supplier of desktop scanning electron microscopes (SEMs), has once again chosen Deben as their preferred supplied of accessories for their Phenom XL range of desktop scanning electron microscopes. Speaking about this exciting new applications development, Karl Kersten, Manager of Applications Engineering at Phenom World, takes up the story:

Phenom-World, the leading global supplier of desktop scanning electron microscopes (SEMs), has once again chosen Deben as their preferred supplied of accessories for their Phenom XL range of desktop scanning electron microscopes. Speaking about this exciting new applications development, Karl Kersten, Manager of Applications Engineering at Phenom World, takes up the story:

“There are several reasons for offering a tensile stage for our Phenom XL. We want to broaden the range of applications on our desktop SEM and our aim is to make SEM imaging and analysis available to every scientist in every lab. We believe that there are many SEM applications for tensile testing but that these do not require a high end floor model SEM. Tensile testing is a way of determining how materials will react when they are pulled apart or pushed together - when a tension force is applied. It is one of the simplest and most widely used mechanical tests. By measuring the force required to elongate a specimen to breaking point, material properties can be determined that will allow designers and quality managers to predict how materials and products will behave in their intended applications. The tensile stage from Deben is a robust device which is as easy to use as a Phenom desktop SEM. It can be loaded into the Phenom XL just like any other sample holder. There is no need to install or prepare any parts inside the SEM which really shortens the time to image. The tensile stage can be used outside the SEM under an optical device and inside the SEM when a higher magnification and better depth of focus is required. This bridges the gap between the light and electron microscopy worlds which could potentially expand the range of users.”

Kersten continued to speak about the choice of OEM partners, “We have a long history working with our partner Deben. Our first development was a temperature controlled sample holder for cooling and freezing samples. We recognize one of the main reasons we work with Deben is their knowledge of what is required to make devices that work successfully in an SEM. This requires broad technical knowledge with expertise in the range of vacuum, electronics, software etc. We have also found that working with Deben has been very straightforward. Their flexibility, pro-active approach and good support make them an ideal OEM partner.”

The Tensile Sample Holder enables users to study materials under tensile and compressive loads. Cyclic testing is also an option. Materials can be characterized by their strength. Compressive strength is the capacity of a material or structure to withstand loads tending to reduce size, as opposed to tensile strength, which withstands loads tending to elongate. In other words, compressive strength resists compression (being pushed together), whereas tensile strength resists tension (being pulled apart). The module allows many different materials to be deformed and stretched at loads of up to 100 kg (1 kN). The maximum load depends on the load cell fitted of which there are two 150 N and 1000 N. The choice depends on the type of sample and the tests being carried out. Applications include the observation of fiber clusters, polymer films, thin metal films, biological and plant materials.

Media Partners