Members Login

Channels

Special Offers & Promotions

Smart approach to method development as new Mastersizer 3000 takes

Reflecting the wealth of engineering

and applications expertise at Malvern Instruments, the company's new

Mastersizer 3000 particle size analyzer takes performance and ease of

use to the highest level. This new system wraps groundbreaking optical

capabilities with software that supports the user every step of the way - from

method development right through to routine measurement - helping operators at

every level to gather appropriate, reliable and reproducible data.

Reflecting the wealth of engineering

and applications expertise at Malvern Instruments, the company's new

Mastersizer 3000 particle size analyzer takes performance and ease of

use to the highest level. This new system wraps groundbreaking optical

capabilities with software that supports the user every step of the way - from

method development right through to routine measurement - helping operators at

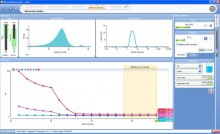

every level to gather appropriate, reliable and reproducible data. Laser diffraction is now the particle sizing technique of choice across multiple industries and applications, but whatever the analytical challenge, developing a robust measurement protocol that defines sampling, sample dispersion and measurement conditions is essential. The Mastersizer 3000 actively streamlines and simplifies this method development process, ensuring that subsequent measurements are simply a matter of routine. Its intuitive browser-style software, embedded applications intelligence and real-time feedback on all measurements serve to guide even novice users to an optimized analytical method for each and every sample.

The Mastersizer 3000 System Measurement Manager allows users to manipulate the parameters that control sample preparation and to gauge the effect in real-time. With wet measurement you can, for instance, observe the results of applying ultrasound to your sample to achieve a consistent size, or increase the stirrer speed to get the bias-free sampling required for repeatable measurement. Similarly with dry measurement, the impact of air pressure on dispersion is immediately clear and carrying out the pressure titration that underpins all successful method development has never been simpler or more intuitive.

Developed methods based on Standard Operating Procedures then streamline measurement to the point of push-button operation and are easily transferred. This ensures true reproducibility from user-to-user, instrument-to-instrument, site-to-site. During routine measurement the Mastersizer continues to provide support, verifying, for example data quality and alerting the user to any problems. The result is reliable, repeatable and relevant data for all.

For further information click here

Media Partners