Channels

Special Offers & Promotions

Significant breakthrough regarding reactivity of Milstein

Chemists from the Chianese Group at Colgate University (NY, USA) have shared kinetic data obtained using the Asynt Multicell 10-position high pressure laboratory reactor in their recent paper, “The Key Role of the Latent N0H Group in Milstein’s Catalyst for Ester Hydrogenation”.

Their characterisation of the mechanisms of Milstein’s catalysts has enabled greater understanding of the reactivity of these catalysts in ester hydrogenation.

These catalysts are used within a multitude of fundamental processes within chemical manufacturing. Development of these catalytic processes is therefore a significant area of improvement for economical and sustainable growth of the chemical industry.

The team initially determined that ruthenium complexes containing PNN-pincer ligands are initially inactive, and upon dehydroalkylation of the pincer ligand, form the active NHEt-substituted derivative, with ethane or propane as a side product. This showed that the latent N-H groups generated were key to the catalytic activity, leading to the discovery of the most active catalyst for ester hydrogenation known to date.

In a separate study, through experiments on PNN- and PNP- ruthenium pincer complexes, they were able to discover that with isopropyl alcohol as the solvent, low catalyst loadings could be used to achieve highly branch selective hydrogenolysis of epoxides without the use of a strong base. They were able to produce high yields of the branched alcohol with minimal catalyst loading from the PNP-pincer complex Ru-MACHO-BH, a commercially available catalyst, much cheaper than alternative catalysts tested.

Hydrogenation reactions are typically carried out under pressure, and therefore require a suitable high-pressure vessel. As the chemists at Colgate University were carrying out a variety of hydrogenations, their vessel had to be safe to operate at various pressures, ranging from 10 to 30 bar.

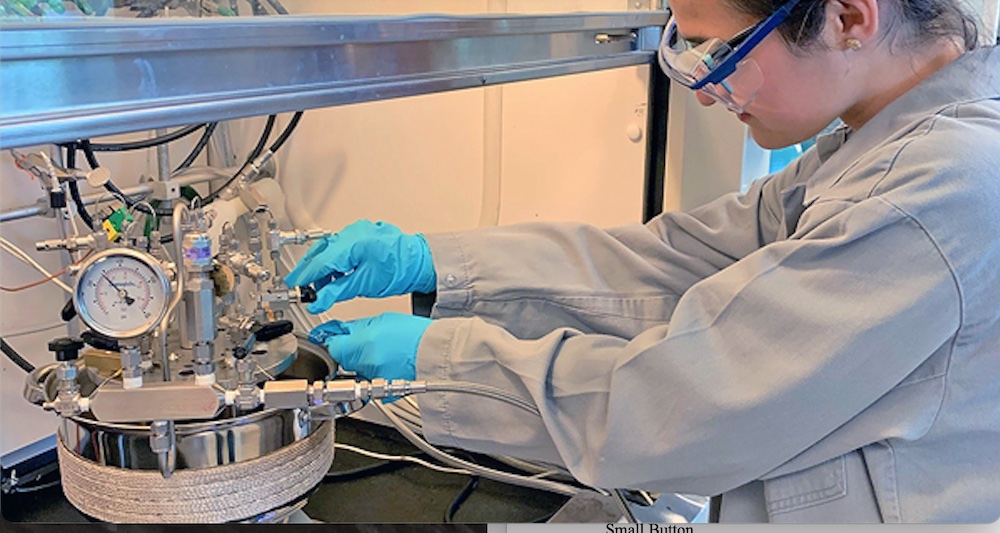

The Multicell pressure reactor used by the Chianese Group who carried out the research detailed above was customised specifically for sampling, aiding the application of catalysis.

The Asynt Multicell allows 10 parallel reactions at high pressure up to 50 or 100 bar, and temperatures up to 350 ?C (depending upon the model purchased) each individual 30 mL vessels. As standard, safety features include a pressure relief valve and gauge however further optional safety measures such as burst disks are available. The Asynt Multicell are widely customisable, with sampling, charging, and individual vessel pressures possible for further screening capabilities. Heating is via standard laboratory hotplate and temperature coupling is enabled by the thermowell to control the temperature of the reaction within the vessels.

About Asynt

Asynt is a leading supplier of chemistry equipment for scientists in industry and academia. With a sales team of trained chemists, Asynt draw upon their in-depth application knowledge to provide a high-level of customer support for its oil-free DrySyn Heating Blocks, CondenSyn waterless condensers, turn-key & bespoke solutions for Controlled Lab Reactors, Flow Chemistry apparatus, Photochemistry systems, Synthesis Tools, Evaporators, Temperature Control Systems, Vacuum Pumps and Lab Safety Equipment plus more.

Media Partners