Channels

Special Offers & Promotions

Micromeritics introduces the Selective Adsorption Analyzer 8100

Delivering precise performance characterization for next generation adsorbents

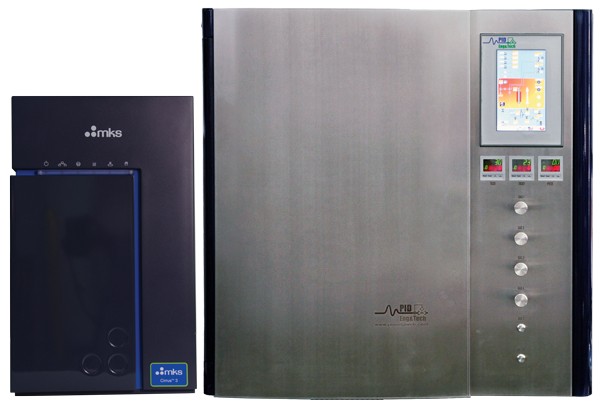

Micromeritics Instrument Corp., a global leader in material characterization technology, has introduced the new Selective Adsorption Analyzer 8100 (SAA-8100), a flexible gas delivery and management system for the precise characterization of adsorbent performance under process relevant conditions. Combining Micromeritics’ widely recognized knowledge of gas adsorption with the tried and tested technology of PID Eng and Tech, a company recently acquired by Micromeritics and renowned for its microreactor and pilot plant technology, it delivers reliable, selective adsorption data for gas/vapor mixtures by mass balance. A highly efficient tool for evaluating the performance of next generation adsorbents, the SAA 8100 is particularly valuable for researchers working in fields such as gas separation, storage and purification, carbon dioxide capture and energy storage.

Adsorbents are defined by their selectivity and capacity for a specific component. Quantifying transient and equilibrium adsorption behavior using relevant gas/vapor mixtures, at commercially relevant temperatures and pressures is therefore essential. Breakthrough analysis, measurement of the concentration of the component of interest at the exit of an adsorption bed as a function of time, is one of the primary ways of gathering this information.

The SAA-8100 incorporates precision mass flow controllers and proprietary, high performance blending valves from PID Eng and Tech. The resulting gas delivery system has minimal dead volume and ensures the precise control of both composition and flow rate. Adsorbent is held in a simple column that uses only 0.05 – 5 g of sample per measurement. A hot box provides accurate, uniform temperature control of the column, column, up to 200°C, with no cold spots. Sample activation up to 1,050°C can be carried out using the software-controlled furnace. Operating pressures can be controlled from atmospheric to 30 bar via a back-pressure valve. The gas detection system and other features such as vapor generation are readily customized for the application(s) of interest.

With the SAA-8100 generating accurate breakthrough curves under well-controlled conditions is simple and straightforward. A wealth of other characterization strategies can also be applied including mixed gas adsorption studies, competitive adsorption assessments, and high-pressure isotherm generation. Vapor generating options are available for those that require them. By exploiting these test capabilities researchers can accelerate new adsorbents into commercial use with efficiency and confidence.

Media Partners