Members Login

Channels

Special Offers & Promotions

Fluid Bed Dryer offers significant advantages over conventional drying techniques

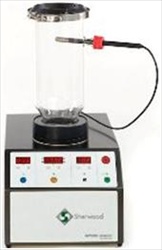

Sherwood Scientific's lab-scale Model 501 Fluid Bed Dryer offers significant advantages over conventional drying techniques and is particularly suited to preparation of small trial samples.

Sherwood Scientific's lab-scale Model 501 Fluid Bed Dryer offers significant advantages over conventional drying techniques and is particularly suited to preparation of small trial samples.

The high rate of heat and mass transfer achieved with a fluid bed dryer ensures much faster and more homogeneous drying than obtained using other methods; such as oven and vacuum drying. Complete drying is usually achieved in less than 15 minutes, with the exact time for a given sample being very repeatable. Inlet air flow rate and temperature settings are closely monitored and adjusted in this modern microprocessor controlled dryer. The Model 501's fluidising action ensures thorough mixing. Hence the temperature to which a sample is subjected is uniform, under control and can be significantly lower than that required in conventional dryers; a real advantage when preparing heat sensitive materials. In addition final product can be produced with uniform, reproducible, moisture content with the appropriate settings and practice if that is a required property of the material at the end of the drying process.

Among the wide range of materials that can be processed are pharmaceuticals, chemicals, minerals, foods, coals, wood chips, plastics, resins, seeds, starches, yeasts, etc.

The high performance characteristics of this instrument allow it to be used for many applications in addition to drying, such as:

- Quick determination of moisture content (e.g. coal, tobacco, food products) by correlation with weight loss over 5 minutes, using specified drying conditions

- Mixing and blending of solids

- Rough classification of particle size (Stokes Law)

For further information email enquiries@sherwood-scientific.com or visit www.sherwood-scientific.com/fbds/501.html

Media Partners