Channels

Special Offers & Promotions

Features to consider when purchasing a Pass-Through autoclave

A double door, or pass-through autoclave provides a pathway for objects into a room. Anything entering or leaving via this portal is sterilised. This is especially useful when either trying to keep biologically hazardous materials inside or out of a room. However, not all pass-through autoclaves are equal.

Let’s have a look at some of the features you should consider when purchasing a pass-through autoclave:

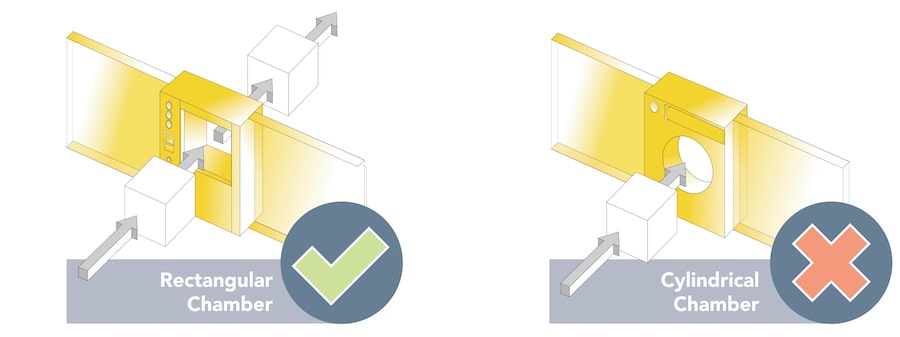

A Rectangular Chamber or a Circular Chamber?

The shape of the autoclave chamber regulates the size and shape of objects that can pass through the autoclave. You should look for an autoclave with a rectangular (or square section) chamber, as this allows for the most efficient use of space. Imagine trying to pass a box through a cylindrical pipe; the pipe is going to have to be much larger than the box. It is much easier to get a square peg through a square hole than a round one. This is especially noticeable when using a pass-through trolley, where the whole trolley bed enters through one door of the autoclave and leaves via the other.

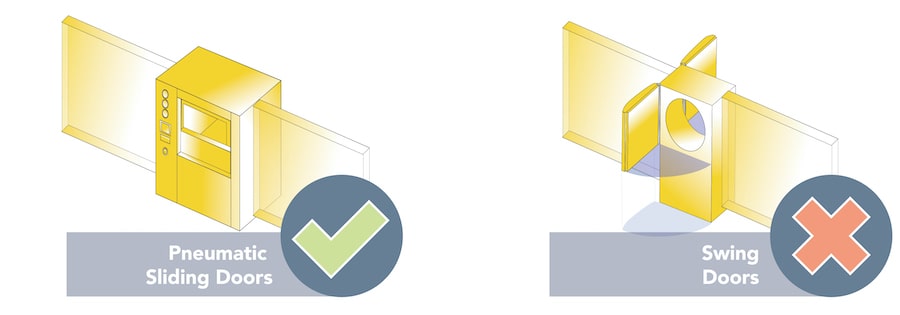

Sliding Doors or Swing Doors?

If space is at a premium, vertically sliding pneumatic doors are a must. Swing doors monopolise space, and with a door on each side, the pass-through autoclave can soon occupy a lot of your valuable room. These space-stealing doors are often hot after autoclaving, adding an extra potential hazard to your laboratory. Sliding doors that disappear into the lower half of the autoclave maintain your free space. They also allow easier loading trolley access, and don’t create a temporary barrier in your cleanroom or corridor.

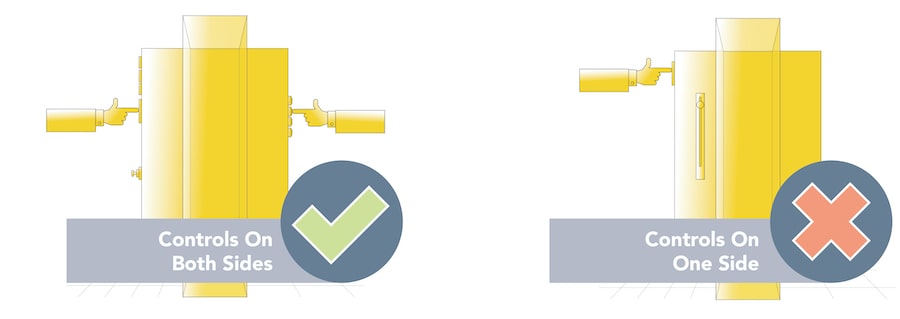

Single Controls or Dual Controls?

If you want to pass objects both ways through the autoclave, it is important to have some level of control on both sides of the autoclave. You’ll want to be able to start and stop autoclave cycles when standing beside either door to maximise the machine’s usability.

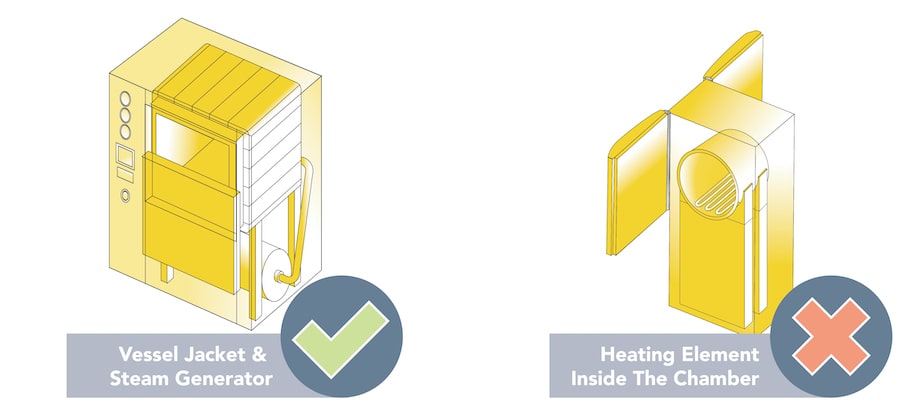

Steam Generator & Jacket or Heaters in Chamber?

With the autoclave acting as a portal between two different spaces, it can easily become a bottleneck if the cycle times are slow. The cycle time largely depends on how fast the autoclave chamber can heat up and cool down. To heat the chamber, steam is used. This steam is either produced inside the chamber by a heating element in a pool of water, or by a steam generator outside the chamber. Heating elements inside the chamber (known as heaters-in-chamber) are cheaper, but slow and inefficient. These heating elements also make the chamber harder to clean, and require more regular maintenance and replacement, meaning your pass-through portal is unavailable more frequently.

An integrated steam generator produces steam faster and more efficiently, making the autoclave cycle faster. Integrated steam generators are also a prerequisite for adding a heating and cooling jacket to the autoclave. This jacket allows both hot steam and cold water to be passed around the outside of the chamber, allowing it to heat up and cool down even faster. To make your pass-through a fast, efficient, and resilient, equip it with an integrated steam generator.

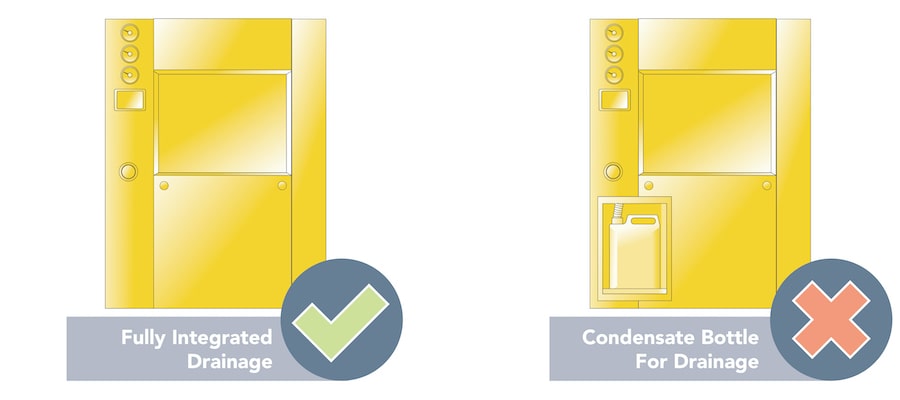

Fully integrated drainage

Some smaller laboratory autoclaves are designed to be moved from room to room. As such, they may have an external bottle for collecting used condensate. This feature is of no benefit to most pass-through autoclaves, as they are mounted in walls and cannot move.

A condensate bottle requires frequent emptying and, if discard waste were put through the autoclave, would not comply with BS2646. It is highly advised to take advantage of the pass-through autoclave’s static nature, and make sure it is plumbed into the drain.

At Astell Scientific, we produce both standardised and fully bespoke pass-through autoclaves for a wide range of industries and specialisms. We understand that all laboratories and cleanrooms are different, and can provide machines that are customised and modified to your needs.

Contact us today to discuss your autoclaving requirements on +44 (0)20 8309 2031 or visit Astell.com for more information.

more news from Astell Scientific

Media Partners