Channels

Special Offers & Promotions

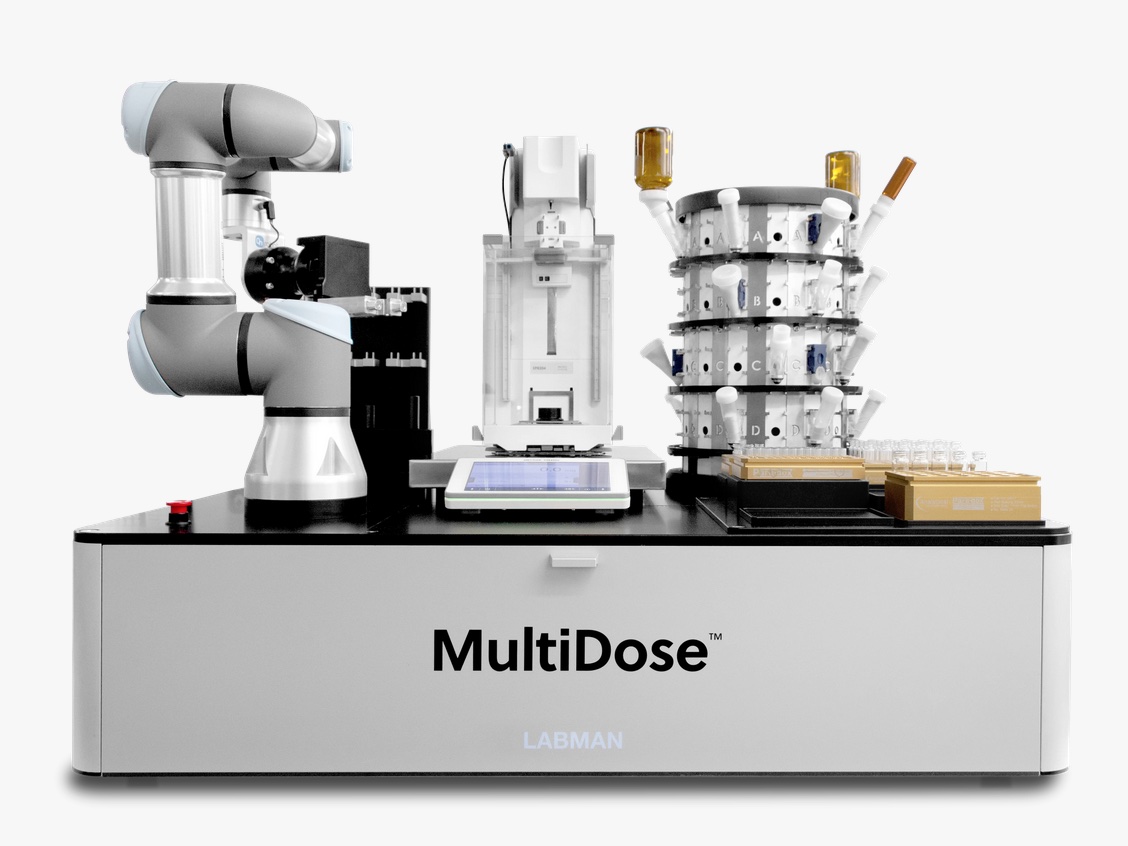

Universal Robots and Labman Automation partner to help bring pharmaceutical products to market quicker

New MultiDose system saves lab technicians up to six hours per experiment

Labman Automation, a UK-based company creating laboratory automation solutions, has partnered with collaborative robots (cobots) manufacturer, Universal Robots, to develop the MultiDose powder dosing system.

The MultiDose system will enable pharmaceutical companies to rollout much needed products for testing, bringing them to market faster. A highly-accurate, automated solid dispensing instrument, it will save technicians up to six hours per experiment, compared to manual processes.

The system requires virtually no training, is user-friendly and intuitive for technicians to use. Increased throughput of a lab is enabled by the ‘walk away’ nature of the MultiDose system, which allows experiments to be performed automatically out of normal working hours.

“With medicine shortages ongoing across UK, EU and US supply chains, the pharmaceutical industry is under pressure like never before. That’s why it’s crucial for pharmaceutical companies to have access to out-of-the-box automation solutions that can be used right away,” says Adrien Poinssot, Global Director for OEM at Universal Robots. “We are proud to have played a role in Labman’s MultiDose to create turnkey solutions that will allow the pharmaceutical industry to be more flexible, reactive and efficient in these challenging times.”

Labman’s MultiDose addresses the rising need from a number of laboratories for a bespoke solution to automate powder dosing with a greater level of usability, while offering the versatility to integrate the system into larger workflows.

A key part of the MultiDose system requires a cobot. Having collaborated with Universal Robots on previous projects, Labman saw Universal Robots as the natural partner. Labman selected the UR3e – a highly flexible cobot arm – which can be easily integrated into an established lab process, without compromising safety, while adhering to strict industry regulations.

When compared to running manual processes, MultiDose saves lab technicians up to six hours on an experiment by improving efficiency. The system requires virtually no training and is very user-friendly and intuitive for technicians to use. Increased throughput of a lab is also enabled by the ‘walk away’ nature of the MultiDose system, which allows experiments to be performed automatically out of normal working hours.

“Having a trusted partner such as Universal Robots has helped us shape and finesse MultiDose to make it the best it can possibly be,” says Matthew Smith, MultiDose Project Lead at Labman Automation. “The Universal Robots arm works out of the box with virtually no training, meaning lab technicians can almost instantly reap the rewards of increased efficiency. The MultiDose automated dosing platform is a solution that hasn’t yet been matched in UK pharmaceuticals and it’s great to see it already being used like any other piece of lab equipment.”

You can read more about the MultiDose case study HERE

Universal Robots aims to empower change in the way work is done using its leading-edge robotics platform.

Since introducing the world’s first commercially viable collaborative robot (cobot) in 2008, UR has developed a product portfolio including the UR3e, UR5e, UR10e, UR16e and UR20, reflecting a range of reaches and payloads. Each model is supported by a wide selection of end-effectors, software, accessories and application kits in the UR+ ecosystem. This allows the cobots to be used across a wide range of industries and means that they can be redeployed across diverse tasks.

The company, which is part of Teradyne Inc., is headquartered in Odense, Denmark, and has offices in the USA, Germany, France, Spain, Italy, the Czech Republic, Romania, Turkey, China, India, Japan, South Korea, Singapore and Mexico.

Universal Robots has installed over 50,000 cobots worldwide.

Media Partners