Channels

Special Offers & Promotions

New generation of intelligent petri dishes

|

|

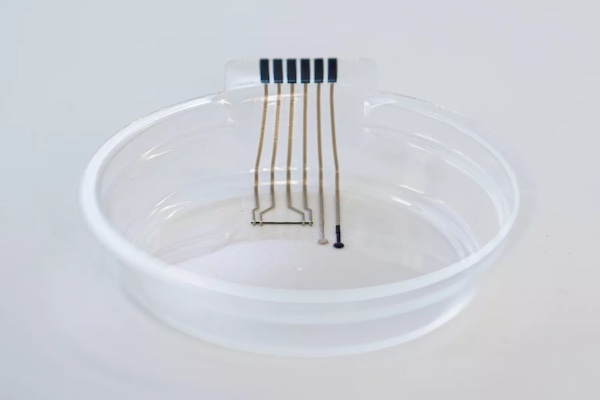

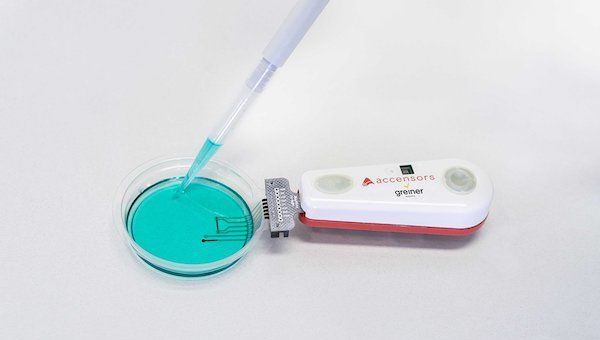

| Intelligent sensors are printed on films and subsequently thermoformed to create smart petri dishes. | Using technology from Accensors, reading out the measurements from the intelligent petri dish is simple via either a scanner or an app. |

Greiner Assistec partners with German startup innoME, to develop smart petri dish

Greiner Assistec is currently working with Accensors, an innoME GmbH business unit specializing in film sensor technology, on a development project aimed at creating printed sensor systems. The first milestone came in the form of a proof of concept for an intelligent petri dish.

Smart, printed sensor systems

In Accensors, Greiner Assistec was able to bring a strong sensor technology partner on board. The aim of this strategic partnership is to offer future customers the option of buying thermoformed plastic parts with printed sensor systems, among other solutions. As part of the pilot project, an initial demo prototype has now been developed, taking the form of a smart petri dish. This involves printing two sensors on the film before putting it through a thermoforming process. And the resulting solution also allows for ongoing monitoring, with the initial prototype making it possible to check up on the pH value and the temperature of the medium in the dish using an Accensors scanner and an app. The resulting data obtained via this process can be harnessed to gain new insights in the realm of research and development.

New generation of intelligent petri dishes

The advantages of the new technology are clear to see – specifically, in the manufacturing process. The intelligent sensor systems can be produced and printed onto the films at an affordable cost and in high volumes. During the thermoforming process, the film printed with the sensor technology is subsequently formed into a three-dimensional shape while retaining the sensors’ functionality, ensuring that the petri dishes can be monitored as effectively as possible. “The development of this smart petri dish has yielded a promising outcome and highlights one of many different possibilities for transforming plastic parts through the use of printed electronics. This makes the initial proof of concept an important step in establishing our new center of excellence for the development of smart plastics solutions in Kremsmünster, Austria,” explains Natascha Andraschek, technology manager at Greiner Assistec.

Eike Wilhelm Kottkamp, founder and CEO of innoME GmbH, likewise sees this project as extremely promising: “The collaboration with Greiner Assistec and implementation of thermoformed film sensors in 3D geometries are a key milestone on our roadmap. Together, we are pleased to be bringing this value proposition to market – and we are eagerly looking forward to the future. At the moment, we are holding preliminary discussions with parties interested in specific applications in the biotech, smart manufacturing, and agricultural sectors.”

Greiner Assistec will continue to work with strong partners such as innoME to deliver the smart petri dish and implement other approaches in the field of intelligent plastics solutions based on printed electronics.

About Greiner Packaging & Greiner Assistec

Greiner Packaging is a leading European manufacturer of plastic packaging in the food and nonfood sectors. The company has enjoyed a reputation for outstanding solutions expertise in the fields of development, design, production, and decoration for 60 years. Greiner Packaging responds to the challenges of the market with two business units: Packaging and Assistec. While the Packaging unit focuses on innovative packaging solutions in the food and nonfood sectors, the Assistec unit is dedicated to producing custom-made technical parts and transit packaging solutions. Greiner Packaging employs a workforce of around 5,000 at more than 30 locations in 19 countries around the world. In 2019, the company generated annual sales revenues of €690 million (including joint ventures), which represents more than 40 percent of Greiner’s total sales.

Accensors is a business unit of innoME GmbH, which was founded in 2015 as a spin-off from the Erwin Quarder Group. Its interdisciplinary team of engineers, chemists, physicists, and biologists develop and implement new sensor solutions at its locations in Munich and Espelkamp, Germany. Accensors offers customized and customer-oriented film sensors that have enjoyed an enthusiastic reception from customers and end users alike, as well as providing valuable and sustainable knowledge through sensor data.

Media Partners