Channels

Special Offers & Promotions

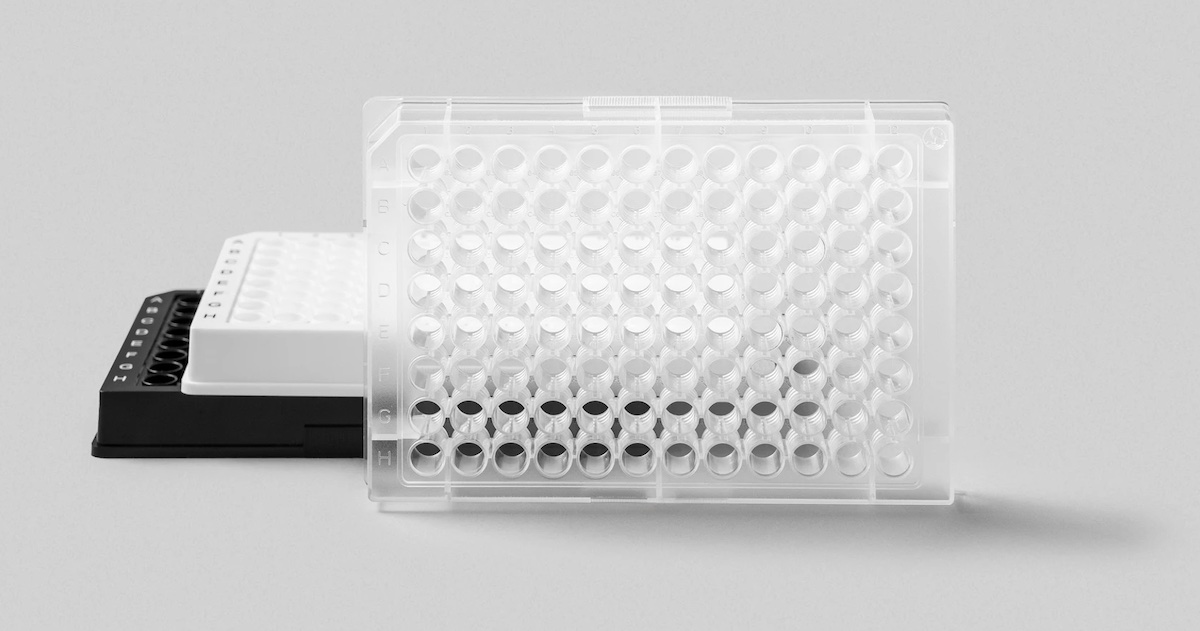

Green Elephant Biotech expands sustainable 96-well plate line for light-sensitive experiments

- Launch of industry’s first sustainable black and white plates made from PLA follows the successful recent launch of Green Elephant Biotech’s transparent 96-well plates earlier this year

- New plates are suitable for light-sensitive experiments, such as those based on fluorescence and luminescence

Green Elephant Biotech GmbH, the world's first company to develop, manufacture and sell consumables for laboratories made from plant-based plastics, is expanding its product line of plant-based 96-well plates with two new additions for fluorescence- and luminescence-based assays. The new black and white microtiter plates broaden the company’s position in the field of sustainable, plant-based laboratory consumables, and offering a climate-friendly alternative for even more laboratory applications.

In January of this year, Green Elephant Biotech launched its first climate-friendly lab consumable – the world's first transparent 96-well plate made from the biopolymer polylactic acid (PLA) – suitable for various routine lab experiments. The introduction of black and white plates now provides a more sustainable alternative for light-sensitive experiments, such as those based on fluorescence and luminescence. This aligns perfectly with Green Elephant Biotech’s motto: "Making sustainability the standard."

"With this plant-based solution for fluorescence and luminescence assays, laboratories can significantly reduce their environmental footprint while maintaining the quality of their research without compromise," explains Dr. Joel Eichmann, Dr. rer. Nat., co-founder and co-managing director of Green Elephant Biotech. "The introduction of sustainable products like our 96-well plates is an important step in making the biopharmaceutical industry more sustainable. We are convinced that our products will make an important contribution to decarbonizing laboratories," adds Felix Wollenhaupt, co-founder and co-managing director.

Valuable research findings often rely heavily on single-use plastic consumables, such as pipette tips, gloves and microtiter plates. Because of the risk of contamination with hazardous materials, they can only be disposed of by incineration, releasing climate-damaging carbon dioxide. Until recently, this environmental impact has been unavoidable for many researchers. But PLA, the material used for Green Elephant Biotech’s 96-well plates, is made from plant starch, from renewable raw materials such as corn. Comparable optical properties, as well as chemical and mechanical stability, enable a seamless transition from products previously available on the market to the PLA-based plates, without compromising the quality of the results.

Green Elephant Biotech’s 96-well plates are now available with a flat bottom in transparent, black, and white and can be purchased directly from the company.

Green Elephant Biotech is the world’s first company to develop, manufacture and distribute consumables for laboratories made from plant-based plastics. With its innovative and sustainable products, Green Elephant Biotech enables the biopharmaceutical industry to bring new and life-changing therapies to patients. The company’s first product include the CellScrew® cell culture system, which provides the biopharmaceutical industry, academic research, and cultured food manufacturers with more sustainable and efficient cell culture. Green Elephant Biotech was spun out of the Technical University of Central Hesse (THM) in 2021 by Felix Wollenhaupt and Dr. Joel Eichmann and currently employs 14 people in Berlin and Giessen.

About Polylactic Acid (PLA)

PLA is a biopolymer from renewable raw materials, like plant starch from corn. This means that, during disposal, the only carbon dioxide that can be released into the atmosphere is the amount that the corn plants previously removed -- as opposed to the additional carbon dioxide released during the incineration of petroleum-based plastic. The production of PLA is also less energy-intensive than making polystyrene. Green Elephant Biotech’s PLA-based products, like its microtiter plates, therefore have a 50% lower carbon dioxide footprint over its entire life cycle compared to fossil fuel predecessors.

Media Partners