Channels

Special Offers & Promotions

CTK Bio Canada Develops Bioplastic Resin Designed to Break Down in Soil and Seawater

CTK Bio Canada has developed a new bioplastic resin designed to biodegrade by both industrial and home composting, as well as in unmanaged environments like soil and seawater, in order to reduce microplastic pollution.

The Company is now undertaking detailed experimental trials with academic partners to further enhance and validate its technology ahead of anticipated commercial rollout in 2022, meanwhile a provisional patent has been filed.

Over 360 million tons of plastic waste are now produced annually, with only 9% of that being recycled. By current estimates, the mass of plastic in the oceans will equal the mass of all fish species combined by 2050. This ecological disaster is an urgent concern, and CTK Bio Canada is aiming to replace conventional plastic used for packaging with a safer, more sustainable alternative.

Bioplastics currently account for only 1% of global plastic production, and much of this requires specialized composting facilities in order to break them down. High costs, issues with mechanical properties, and poor long-term stability have also limited the broader commercial uptake of bioplastics.

Now, CTK Bio Canada believes they have found a solution. Founded by JK Park and Daniel Shum, the company is the new Canadian subsidiary of Korean cosmetic giant CTK Cosmetics (“CTK”). In a push to reduce their environmental footprint, CTK has invested heavily in the research being done by the Canadian team.

“CTK is the perfect strategic partner with global reach” said Shum, the Company’s Chief Operating Officer. CTK shares our vision for the future of the packaging industry, and has been a perfect fit.

Park and Shum developed their technology in partnership with Profs. Zachary Hudson and Emily Cranston, experts in plant-based materials technology at the University of British Columbia. Hudson holds the Canada Research Chair in Sustainable Chemistry, and Cranston is currently the President’s Excellence Chair in Forest Bio-Products. Once the formulation had been developed, prototyping began with the Polymer Materials and Manufacturing group at McMaster University; Heera Marway, Vladimir Gritsichine, Profs.Michael Thompson and Li Xi.

“Canada has tremendous strength in the bioresources sector, giving us a real competitive edge,” said Park, CEO of CTK Bio Canada. “The goals we set for ourselves were ambitious,so we wanted to work with the very best in the field to produce a material that could outperform what was currently on the market.”

The Company’s materials are designed to overcome a critical barrier in the bioplastics space – the ability to degrade in water. While increased use of bioplastics are a positive sign for the environment, Shum and Park knew that too much of it was still ending up in rivers and oceans where they couldn’t easily biodegrade. CTK Bio Canada’s materials are designed to break down not only if disposed of in the green bin, but also if they end up discarded to the environment. The materials should degrade only to nontoxic byproducts,while also remaining compatible with equipment for manufacturing traditional plastics.

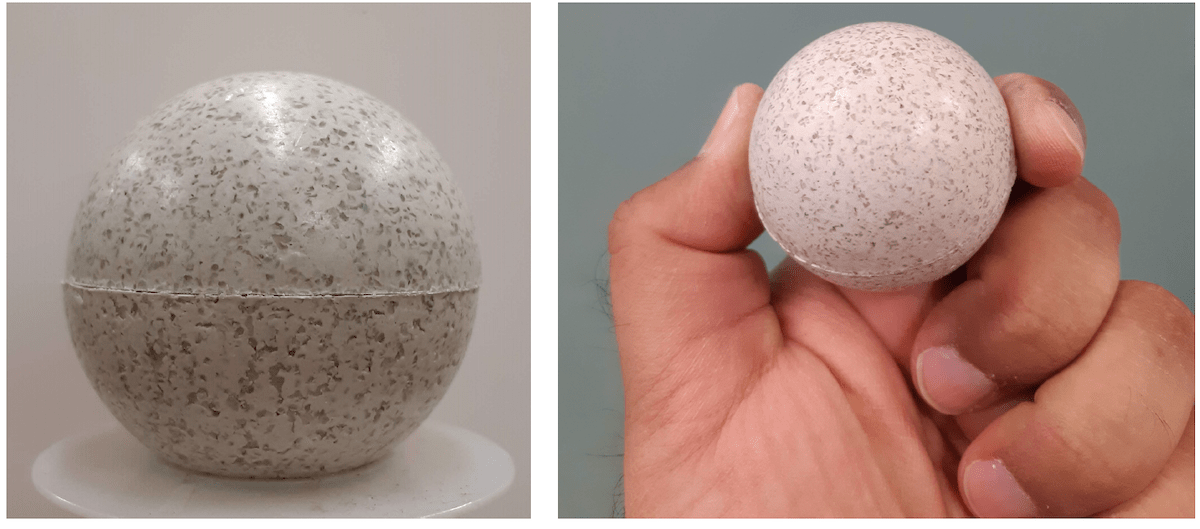

“We wanted something that our customers could use as a drop-in replacement for conventional plastics without having to replace their existing manufacturing lines,” said Cranston, the Company’s Chief Scientific Officer. Most importantly, the team believes they can achieve these milestones in materials science while keeping costs competitive with petroleum-based plastics. Initial prototyping has already been completed on a series of plastic parts and films, with detailed testing planned in 2021 to validate the material’s degradability. The Company has also released a white paper on its website describing the formulation and design in more detail. CTK Bio Canada aims to commercialize its innovation starting in 2022.

Media Partners