Channels

Special Offers & Promotions

Substituting chromium

publication date: Jul 25, 2019

|

author/source: Metrohm AG

One of the biggest players from the aerospace industry has replaced chromium in their anodizing process of aircraft parts by a mix of sulfuric and tartaric acid (TSA, Tartaric Sulfuric Anodizing).

Metrohm developed a new method allowing this customer to determine both acids quickly and reliably using the same sensor, a highly sensitive, fast responding thermometer. An Application Note describing this application is available free of charge from Metrohm.

Replacing chromium by less hazardous substitutes such as sulfuric and tartaric acid helps reduce the environmental impact of anodizing metal substrates for corrosion protection. Potentiometric titration is the standard method used to monitor the levels of these acids. This method, however, requires two titrations to be performed with different electrodes and requiring different solvents.

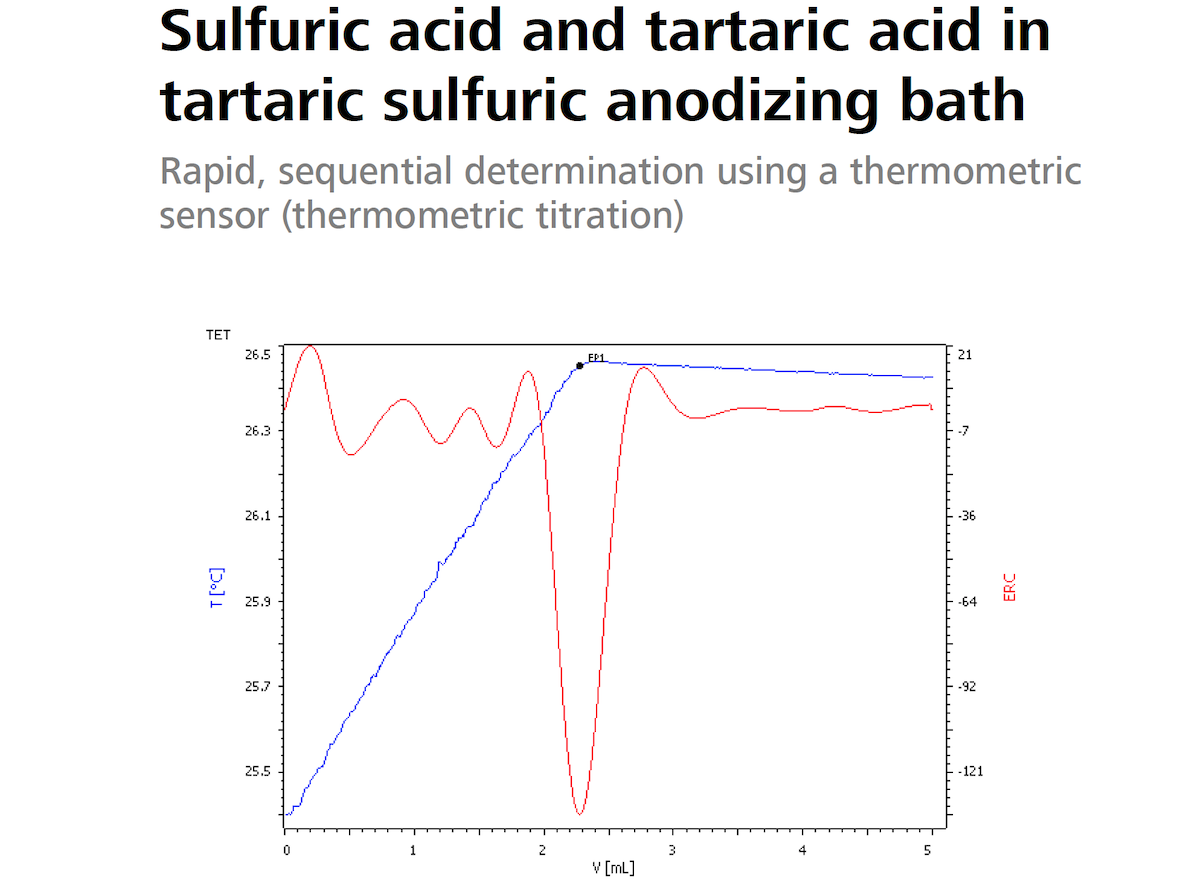

Thermometric titration, on the other hand, allows monitoring sulfuric and tartaric acid using the same sensor in the same matrix. This sensor, a highly sensitive, fast responding thermometer, determines the endpoint of the reaction when no change in the temperature of the sample solution (reaction enthalpy) is registered any more.

Compared to potentiometric titration, thermometric titration is also faster and more convenient (no sensor maintenance required) to use. On a fully automated system, determination of sulfuric acid and tartaric acid takes about 7 minutes.

Media Partners