Channels

Special Offers & Promotions

Sub-Micron Filter for High Temperature & Hazardous Process Environments

A white paper from Porvair Filtration Group describes the development of a micro porous sintered metal-ceramic membrane filter capable of absolute filtration to 0.5 microns in noxious or hazardous environments at temperatures of 500 °C and beyond.

A white paper from Porvair Filtration Group describes the development of a micro porous sintered metal-ceramic membrane filter capable of absolute filtration to 0.5 microns in noxious or hazardous environments at temperatures of 500 °C and beyond.The process industry demands filters that can withstand the most extreme and aggressive conditions of temperature, pressure and corrosion, whilst safeguarding operators and systems from particulates and ensuring environmental protection. As precious metal catalysts used in industrial processes become ever more expensive and are used in greater amounts, fine filters capable of withstanding the process environment offer a viable route for higher yield recoveries.

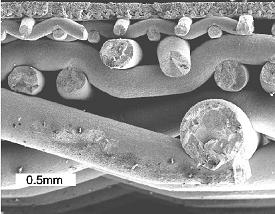

Most porous metal filters are incapable of removing particles smaller than 4 microns. The Sinterflo® filters, under development by Porvair, are shown to improve filtration by almost an order of magnitude. Scanning electron photomicrograph and porosimetry, bubble point, permeability and efficiency data, for both gaseous and liquid environments, are presented.

A copy of the described white paper is available by contacting Porvair Filtration Group on +44-1489-864330 / +1-804-550-1660 or email info@porvairfiltration.com.

Porvair Filtration Group has supplied the process industry for over 25 years, with innovative and performance driven filtration equipment (elements, cartridges and vessels). The company has provided highly specialised filtration solutions for use throughout the manufacturing process and has proven filtration solutions for the production of chemicals such as nitric acid, maleic anhydride, caprolactum, hydrogen peroxide, sulphuric acid, phosphoric acid, magnesium nitrate, as well as HDPE and LLDPE. By using the latest in metallic filter media technology, Porvair Filtration Group are able to provide improved performance, and reduced plant operating costs, enabling longer campaigns and greater materials recovery.

Porvair Filtration Group has supplied the process industry for over 25 years, with innovative and performance driven filtration equipment (elements, cartridges and vessels). The company has provided highly specialised filtration solutions for use throughout the manufacturing process and has proven filtration solutions for the production of chemicals such as nitric acid, maleic anhydride, caprolactum, hydrogen peroxide, sulphuric acid, phosphoric acid, magnesium nitrate, as well as HDPE and LLDPE. By using the latest in metallic filter media technology, Porvair Filtration Group are able to provide improved performance, and reduced plant operating costs, enabling longer campaigns and greater materials recovery.Porvair Filtration Group is an international leader in the development and supply of materials and products for applications in filtration and separation. Their expertise in a wide range of media and the dedication of their design, manufacturing, sales, test and research teams ensure they are at the forefront of filtration technology, delivering world class performance to the Aerospace, Defence, Nuclear, Energy, Chemical Process, Industrial Process, Water Treatment, Printing and Life Science markets. With offices and manufacturing sites located in the UK, Europe and the USA combined with a world-wide network of market representatives and distributors, they pride themselves on their continuous innovation and research to meet global demands.

Media Partners