Channels

Special Offers & Promotions

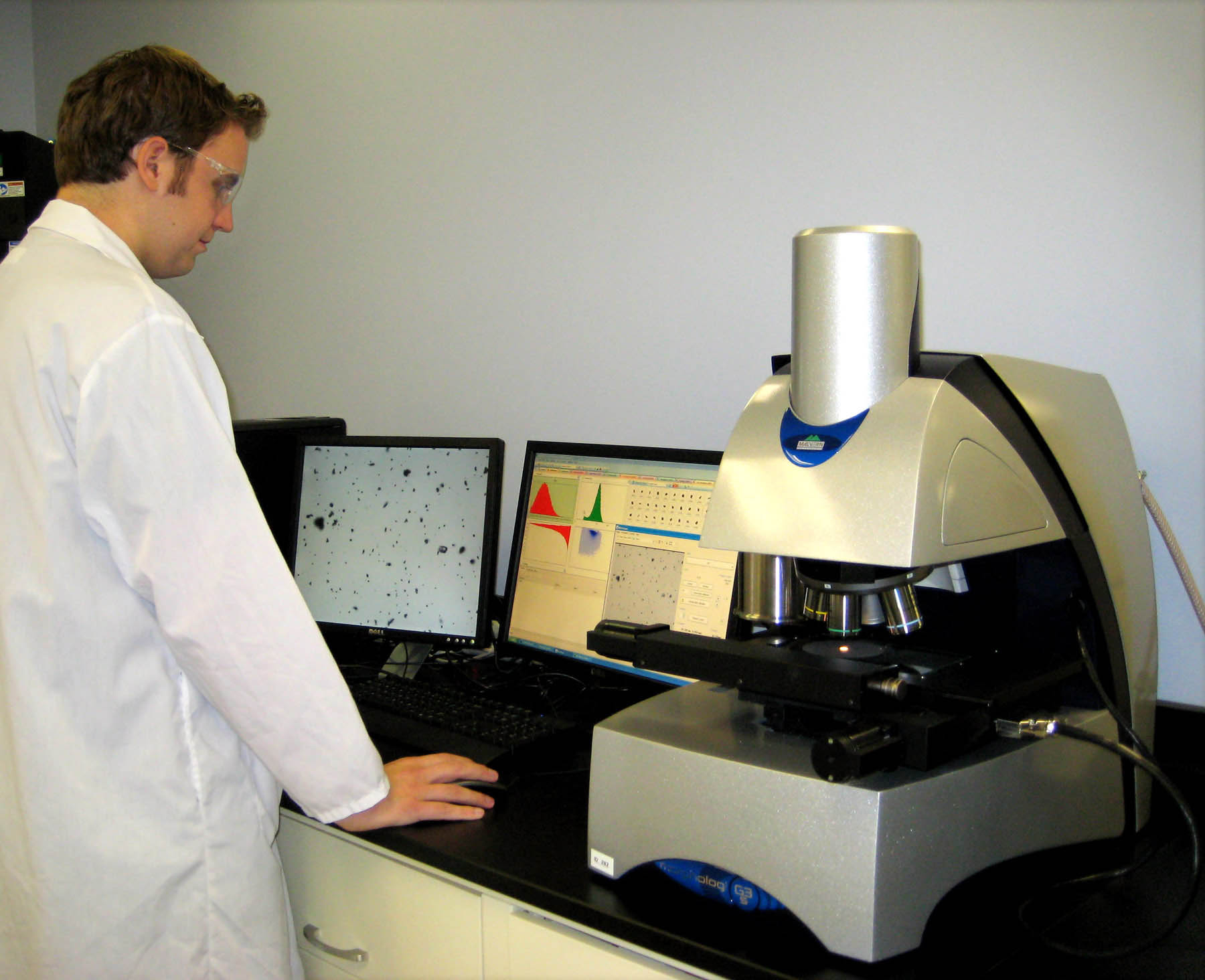

PTL adds Malvern

Particle Technology Labs (Chicago, USA) has added the Morphologi G3 from Malvern Instruments to the extensive range of technologies it has available for analyzing its clients' materials. PTL, which is based in Chicago, is a leading service laboratory dedicated to quality particle sizing and characterization. Operating under cGMP, PTL is also FDA registered, DEA licensed and holds an ATF permit. The Morphologi G3 fully automated microscope based image analysis system delivers information on particle shape as well as size. Having used manual microscopy techniques for some time, automation was a high priority for the PTL team, and influential in their decision to purchase the system.

Particle Technology Labs (Chicago, USA) has added the Morphologi G3 from Malvern Instruments to the extensive range of technologies it has available for analyzing its clients' materials. PTL, which is based in Chicago, is a leading service laboratory dedicated to quality particle sizing and characterization. Operating under cGMP, PTL is also FDA registered, DEA licensed and holds an ATF permit. The Morphologi G3 fully automated microscope based image analysis system delivers information on particle shape as well as size. Having used manual microscopy techniques for some time, automation was a high priority for the PTL team, and influential in their decision to purchase the system.

Bill Kopesky, PTL's VP of Analytical Services, confirms the growing need to understand the importance and effects of particle shape. "We have often supplemented laser diffraction particle size distribution data and other techniques which assume equivalent spherical diameters, for example, with microscopic examination and the acquisition of representative images of the particles," he said. "Increasingly now our clients want to know even more about their materials, to be able to elucidate process differences perhaps, or for finer discrimination between two samples."

"Not only has the Morphologi G3 allowed us to move away from manual imaging methods, we can now process large numbers of images in many different ways and examine a wide variety of parameters to provide more detailed information and the extra insight required. And, it has quickly become our instrument of choice for characterizing elongated and non-spherical particles where applications allow."

Currently PTL uses the Morphologi G3 primarily for method development and troubleshooting, and mostly for dry powders, for which the system has an integral dispersion unit:

"We have been impressed with the capabilities of the automated dispersion system," said Mr Kopesky. "Also the wide particle size range that can be measured using multiple objectives means that we do not need to prepare multiple samples. This combination of speed, automation and walkaway capability helps us maximize throughput and make best use of operator time."

PTL also has liquid dispersion capabilities with the instrument by using a wet cell accessory. In addition, they have been able to assist clients in the filtration industry by collecting dilute particle suspensions onto filters and using episcopic illumination to measure the collected particulate using the Morphologi G3.

For more information about the Morphologi G3 visit www.malvern.com/morphologi

For details of PTL go to www.particletechlabs.comMedia Partners