Channels

Special Offers & Promotions

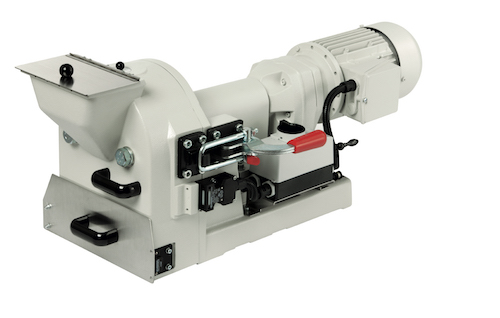

Disk Mill PULVERISETTE 13 Classic Line

The Disk Mill PULVERISETTE 13 classic line is our recommendation for all processing laboratories with a continuous delivery of brittle to very hard materials for batch or continuous fine grinding.

The maximum feed particle size is approx. 20 mm edge length. The fineness attainable (d50) is down to approx. 12 mm (largest gap width) or 0.1 mm (smallest gap width).

The maximum throughput of 150 kg/h depends on the gap setting and the hardness of the sample. The relatively large throughput enables it to be used in the pilot scale or in the small size production, for example: slag-disintegration for the reclamation of precious metals.

Typical fields of application:

Mining and steel industries: Ores, coal, coke, slags

Ceramics: Steatite, sintered ceramics, electrotechnical porcelain, fire-proof clay

Rocks and soils: Bauxite, slags, quartz, clinker, gypsum, chalk

Glass: Frits, glass types, raw materials

Soil research: Dried soil samples, sewage sludge, hydrological sediments, drilling cores

Method of operation:

The material to be ground is crushed between two counteracting grinding disks with course radial toothing on the inside as a result of compressive and shearing stresses. The staged toothing means that the material is pre-ground in the inner chamber of the grinding disks before being finely ground in the outer chamber.

The gap width between the two grinding disks is set from the outside – also during operation – and determines the fineness of the end product.

Features of performance:

- reproducible grinding results through accurate gap setting (exactly 0.1 mm)

- precision adjustment for setting gap

- sight glass for checking gap width

- centrally located toggle-type fastener for grinding chamber

- divided, hinged grinding chamber

- 4 different materials for grinding disks, to ensure that contamination of the samples through abrasion of the grinding elements is avoided during processing.

- grinding disks easily accessed and replaced

- life expectancy of grinding disks can be doubled by changing the rotational direction of the motor

- simple cleaning and dust-free grinding due to dust exhauster connection

- continuous fine grinding from 95 mm to 0.1 mm in a single process through combination with the Jaw Crusher PULVERISETTE 1 classic line

- can be adjusted to individual throughput requests (optional conversion)

Media Partners