Channels

Special Offers & Promotions

Further Improving Efficiency in Laboratory Testing

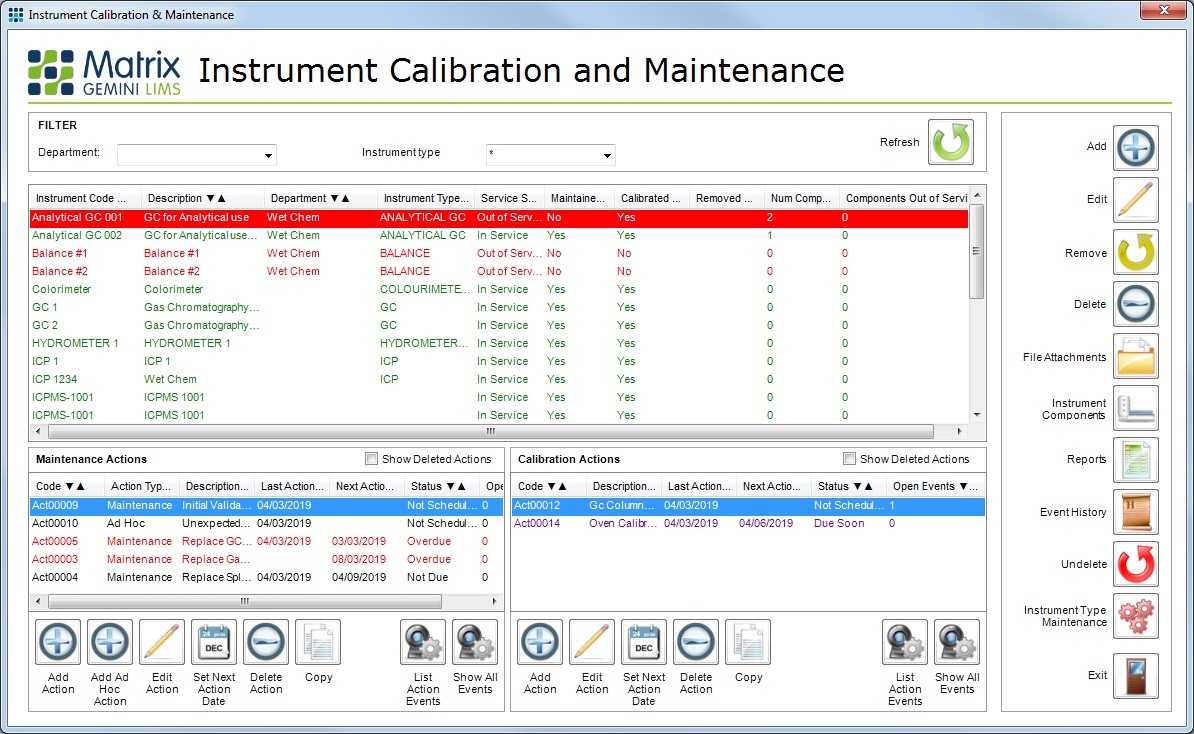

The Instrument Calibration & Maintenance System (ICMS) for the Matrix Gemini LIMS from Autoscribe Informatics provides busy laboratories with another tool to improve quality and compliance as well as drive efficiency.

Proactively scheduling the calibration and maintenance of every piece of equipment in a timely manner ensures maximum instrument availability within the laboratory. Their operational status and audit history can also be tracked automatically to prove compliance. It also avoids entering results against an un-calibrated instrument or one that has not been maintained correctly by providing immediate feedback on availability at the time the results of a particular analysis are entered.

Details on calibration include scheduling of calibration intervals and the permitted instrument calibration limits. Actual calibration results are checked automatically against these limits and out of limit results will be flagged with the instrument status automatically changed to make it unavailable.

ICMS is applicable to any equipment in the laboratory. By keeping a record of all equipment within the laboratory together with a history of all maintenance events for audit purposes, the laboratory can demonstrate that it follows standard calibration and maintenance procedures. ICMS can provide reminders of pending calibration and maintenance tasks with an automatic change of status occurring when calibration or maintenance is overdue and after it has been performed.

In addition, all faults, breakdowns and non-routine occurrences can also be recorded. By showing the time, date, user and description of the problem, all maintenance issues can be tracked. Especially useful in multi-laboratory/multi-site operations is the ability to record the location of the equipment so it can be found quickly.

A hierarchical list of instrument sub-components may be associated with the equipment along with their part number and supplier information to allow easy re-ordering of spares. Every component in the hierarchy can be independently maintained and/or calibrated ensuring the equipment is only available for laboratory work if all the components and also within their maintenance and calibration period.

Media Partners