Channels

Special Offers & Promotions

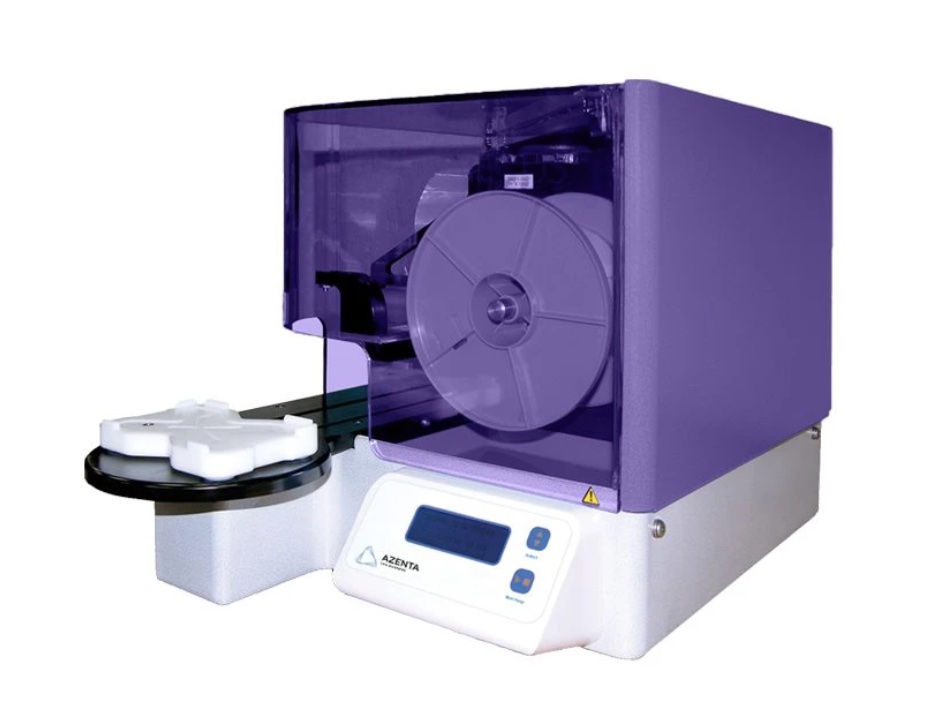

Automated plate seal remover boosts lab performance and efficiency

The Automated Plate Seal Remover from Azenta Life Sciences is a compact system for removing seals from a wide range of microplates at the single touch of a button, without damaging the plate or seal.

Hands-on removal of a seal from a microplate is a routine, seemingly undemanding laboratory task. However, removing and/or replacing tens or hundreds of seals at a time on a repetitive basis can be challenging, particularly in high-throughput and high-content screening laboratories.

Even in labs that invest in automated liquid handlers or storage robotics, the unsealing and resealing of plates for sample access often remains a tedious, time-consuming, and error-prone manual process.

Designed for unattended operation, the Automated Plate Seal Remover is an ideal solution for life science labs that routinely remove microplate seals. It streamlines workflows by eliminating manual bottlenecks, helping to protect sample integrity and minimize degradation by reducing time spent on the benchtop.

With its unique design, the Automated Plate Seal Remover eliminates the need for mechanical removal mechanisms which can be prone to failure. Each plate is passed under a freshly exposed section of the patented de-sealing tape, which gently lifts and peels away the seal as it adheres to the tape. The device is engineered to hold plates securely in place, ensuring consistent removal—even for the most stubborn seals.

The Automated Plate Seal Remover offers precise, automated peeling—eliminating the need for tedious, time-consuming manual removal and reducing the risk of cross-contamination from sample run-off. Capable of processing up to 200 plates per hour, it accelerates workflows, increases throughput, and frees up valuable research time. While it functions seamlessly as a standalone system, integration into robotic workflows transforms it into a fast, reliable, walk-away solution—delivering smoother operations, minimized contamination risk, and enhanced lab productivity.

Recent news from Azenta Life Sciences

Media Partners