Channels

Special Offers & Promotions

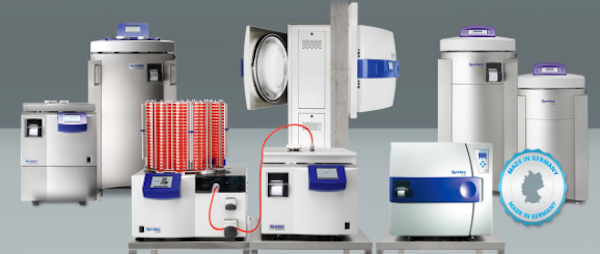

Systec Introduces a New White Paper and Services for New and Existing Customers

The glass test according to Ph. Eur. 9.6 – Systec is ready

Water-resistant glass containers are a prerequisite for countless industries, from chemicals to food production. The European Pharmacopoeia (Ph. Eur.) determines how water resistance can be determined with the so-called glass test. Ph. Eur. Version 9.6., which came into force a few months ago, has further tightened the requirements for this test. This prompted Systec GmbH to issue a new white paper on carrying out the test and to point out the company’s services related to glass tests.

Systec provides support for the glass test

The new white paper will be made available to interested companies free of charge, with the aim of establishing best practices in carrying out glass tests on the basis of both Ph. Eur. 9.6 and proven practical experience. For this reason, the white paper provides a detailed explanation of how to conduct the heat treatment test in accordance with ISO 4802.

In addition, the document provides clear information on the requirements placed on autoclaves used to carry out the glass test, as per Ph. Eur. 9.6. Systec's customers can count themselves lucky: The market leader's highly advanced autoclaves meet all standard requirements for carrying out valid glass tests, a clear technical advantage on the international autoclave market.

Further services for carrying out tests according to Ph. Eur. 9.6

In addition to the white paper, Systec also provides customers with practical assistance and further information on carrying out glass tests. Interested companies can look forward to additional validation hints based on practical experience as well as tested sample parameters for adjusting existing devices.

Companies that have decided to purchase new Systec autoclaves in connection with converting their test procedures to Ph. Eur. 9.6 can further benefit from a special service: Upon request, Systec will validate new equipment based on your specific load directly at the factory. Therefore, most of the necessary validation work is eliminated for the customers, and the results are completely reliable.

Media Partners