Channels

Special Offers & Promotions

Enterprise Labeling White Paper Reveals Four Ways to Enhance Supply Chain Agility and Reduce Costs

The white paper “Adopting Next Generation Labeling Technology Enhances Enterprise Agility and Reduces Costs” published by NiceLabel identifies the hidden costs, inefficiencies and risks resulting from legacy labeling operations and explains why a modern label management platform is well suited to current enterprise and extended supply chain needs.

In today’s networked economy, organizations are challenged with volatile market requirements, massive connectivity driven by the "Internet of Things", and increased product, process, and supply chain complexity. Enterprises are continually looking deeper into their operations and farther across their supply chains for opportunities to become more efficient. Labeling is frequently considered a background process that does not get any attention until it causes a problem. As a result, bar code and RFID labeling practices and software have become dated at many enterprises, and have not kept pace with changing business needs.

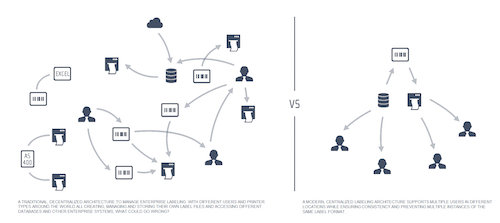

The new generation of label management solutions gives many enterprises a strong opportunity to reduce costs, improve agility and reduce the risk of production shutdowns and non-compliance with labeling requirements. Migrating from decentralized labeling to a modern, centralized solution generally helps organizations in four ways:

? Improves agility by reducing the time needed to create, maintain and update label files, introduce new products and respond to customer requests. Enterprises that convert from decentralized labeling often find thousands of redundant label files that can be eliminated and consolidated into a few consistent templates;

? Raises qualityby preventing inconsistency and eliminating latency from exchanges with enterprise systems; enhanced quality also helps prevent shipping delays and production line shutdowns that result from labeling errors or system failures. Tighter control prevents mislabeling, which reduces the risk of recalls;

? Reduces direct and indirect costsby lessening the labor, time and expertise required to maintain label formats, make changes and create new labels. Indirect savings come from reduced labeling errors, improved compliance and better brand consistency;

? Enhances collaborationwith business partners by making the enterprise more responsive to change requests and by enabling advanced labeling techniques that can help deter diversion and counterfeiting.

Media Partners