Channels

Special Offers & Promotions

Automobile Manufacturer Uses IR Thermography to Uphold Quality Standards

FLIR Advanced Thermal Solutions has announced a new application story that describes how AUDI AG is using infrared thermography to uphold its quality standards.

FLIR Advanced Thermal Solutions has announced a new application story that describes how AUDI AG is using infrared thermography to uphold its quality standards.

"Vorsprung durch Technik" has been the motto of automobile manufacturer Audi for decades. Driven by this approach, the group now also makes extensive use of FLIR thermal imaging technology for testing of supplied parts and internally developed engines to prevent expensive product recalls and to meet its exacting quality criteria.

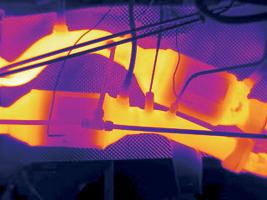

The application story describes how thermal imaging cameras are being used to test all parts - from simple items such as transmission belts to complex ones such as turbochargers or catalytic converters before they are cleared for production. A thermal imaging camera is also used on the engine test-bed. New engines are put on trial to determine heat build-up and distribution as well as the determination of the failure point. Audi also uses a FLIR Systems infrared camera to test interior furnishing materials such as leather, wood and synthetics on wear and tear and material resistance, including under extreme climate conditions.

A copy of the Audi application story is available to download from www.flir.com/thermography/eurasia/en/content/?id=25622 or by contacting FLIR Advance Thermal Solutions on telephone +31 (0)76 5794 176.

Pioneers in all aspects of infrared technology, FLIR designs, manufactures, and supports thermal imaging systems and subsystems for industrial, scientific, governmental, commercial, and firefighting applications. With a 40-year history of infrared innovation, over 100,000 systems in use worldwide, and development centres and sales offices in over 60 countries, FLIR is the world leader in thermal imaging technology.

Media Partners